Small Sample Testing

In recent years, the requirement for small sample testing is emerging, driven by the need to obtain mechanical material properties when only (very) limited quantities of material are available. The limited availability of material can be inherent to its structural size or because the material is very expensive, rare, irradiated or only produced on lab-scale. The industry trend towards Engineering Critical Assessment (ECA) and life extension of ageing assets also requires skills and tools in small sample testing. The recurrent request is to obtain as much valuable information (in terms of quantifiable mechanical properties) from very small (mm scale) samples.

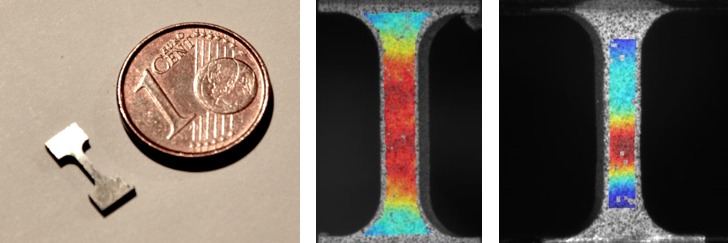

DyMaLab has designed and developed static and dynamic test infrastructures for tensile and compressive testing of purpose-designed miniaturized samples. The home-grown small sample test setups include a micro test device for the quasi-static strain rate regime, and a bespoke small-scale Hopkinson bar for dynamic experiments.

The DyMaLab setups, skills and competencies in small sample testing can be applied for e.g.

- Characterization of the heterogeneous properties of welds and functionally graded materials

- Characterization of lab samples produced by severe plastic deformation

- Characterization of mechanical properties of thin films and coatings

- In-situ observation of deforming samples in microscopes

Technical Specifications

- Static load cells of 200 N, 1 kN and 5 kN

- Static speed range of 0.0005 mm/s to 0.016 mm/s

- Symmetrical clamp displacement, travel up to 20 mm

- Digital Image Correlation to capture local strain fields

- Two 5 Mpxl cameras for full-field sample deformation measurements

- Bespoke small-scale Hopkinson bar setup for dynamic testing at strain rates up to 1000 s-1

Key publications

- Hertelé S., Bally J., Gubeljak N., Stefane P., Verleysen P. and De Waele W., Characterization of Heterogeneous Arc Welds through Miniature Tensile Testing and Vickers Hardness Mapping, Materiali in Tehnologije, vol. 50(4), pp. 571-574 (2016)

- Bally J., De Waele W., Verleysen P., Gubeljak N. and Hertelé S., Characterisation of Weld Heterogeneity through Hardness Mapping and Miniature Tensile Testing, Sustainable Construction and Design, vol. 6 (2015)