Failure of pipeline girth welds subjected to longitudinal plastic strains

Under certain circumstances, girth welded pipelines can be subjected to significant plastic deformations during installation and/or operation. Example causes of these deformations are ground settlements and earthquakes in the case of on-shore pipelines, and bending during reeling of off-shore pipelines. Strain-based design studies the structural response and integrity of welded pipelines subjected to global plastic deformation, and is of great economical and ecological importance for a wide range of pipeline projects.

Pipeline welds should fulfil very strict quality demands, but inevitably show defects (e.g. slag inclusions, lack of fusion). In combination with the occurrence of complex microstructures with potentially decreased mechanical properties (e.g. the coarse-grained heat-affected zone), these defects make welds the critical link when it comes to the structural integrity.

This project aims to investigate and develop methods that are used to assess the acceptability of weld defects in a strain-based context. This is achieved by a combination of experimental and numerical research. The experimental research focuses on the structural response of Medium Curved Wide Plate (MWP) tension specimens. An MWP specimen is a sample of a pipeline girth weldment, which is deliberately notched in the weld region and subjected to plastic tensile deformation. The application of advanced measurement techniques such as optical field deformation measurements (digital image correlation) and unloading compliance analysis allows to investigate the strain distribution around the notch and crack initiation followed by stable crack growth.

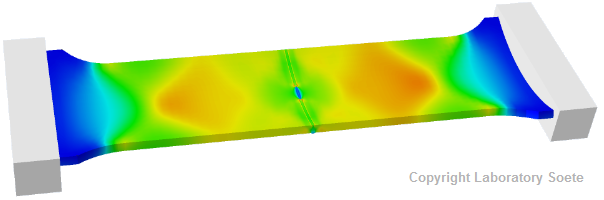

The numerical research consists of finite element analysis of large scale girth weld tension tests, such as Curved Wide Plate (CWP) tension tests (Figure). The results of these analyses are used to (a) support the experimental results, and (b) identify key parameters that influence the structural integrity of flawed pipeline girth welds. The latter is achieved with an acceptable number of simulations using a Design Of Experiments (DOE) approach. Example parameters considered are:

- flaw dimensions and position;

- tensile properties of pipe material, weld material and heat-affected zone;

- geometrical properties, such as pipe diameter and thickness.