Microstructural Influence on Mechanical Properties of High Strength Pipeline Steels

Hostile environments as well as pipeline installation conditions may impose plastic deformations to the transport pipeline. In such situations, where the conventional stress based design is an insufficient basis for pipeline integrity assessment, strain based design (SBD) concepts must be considered.

To ensure the pipeline integrity it is important to define the maximum allowable global strain. This so-called strain capacity has to be greater than the imposed strain demand, in order to sustain the imposed plastic deformation. As a consequence, a deeper understanding of the pipe strain capacity is a fundamental aspect to be discussed.

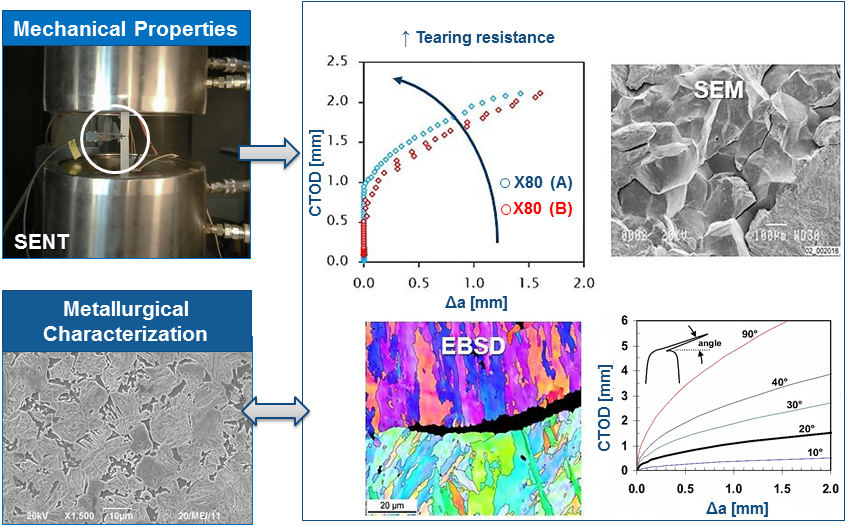

High strength line pipe steels (HSS) are designed to provide better mechanical properties and/or greater strain capacity to sustain imposed plastic deformation. In order to promote a high strain capacity, HSS steels for strain-based design applications must have sufficient toughness and high deformability as well as higher strain hardening, which mean a lower yield to tensile (Y/T) ratio and, also a higher uniform elongation (e[m]).

These key material parameters are governed by both steelmaking (metallurgical design) and further processing (final mechanical properties). Thus, an accurate description and determination of stress-strain behaviour and toughness properties are key points in performing a strain based assessment.

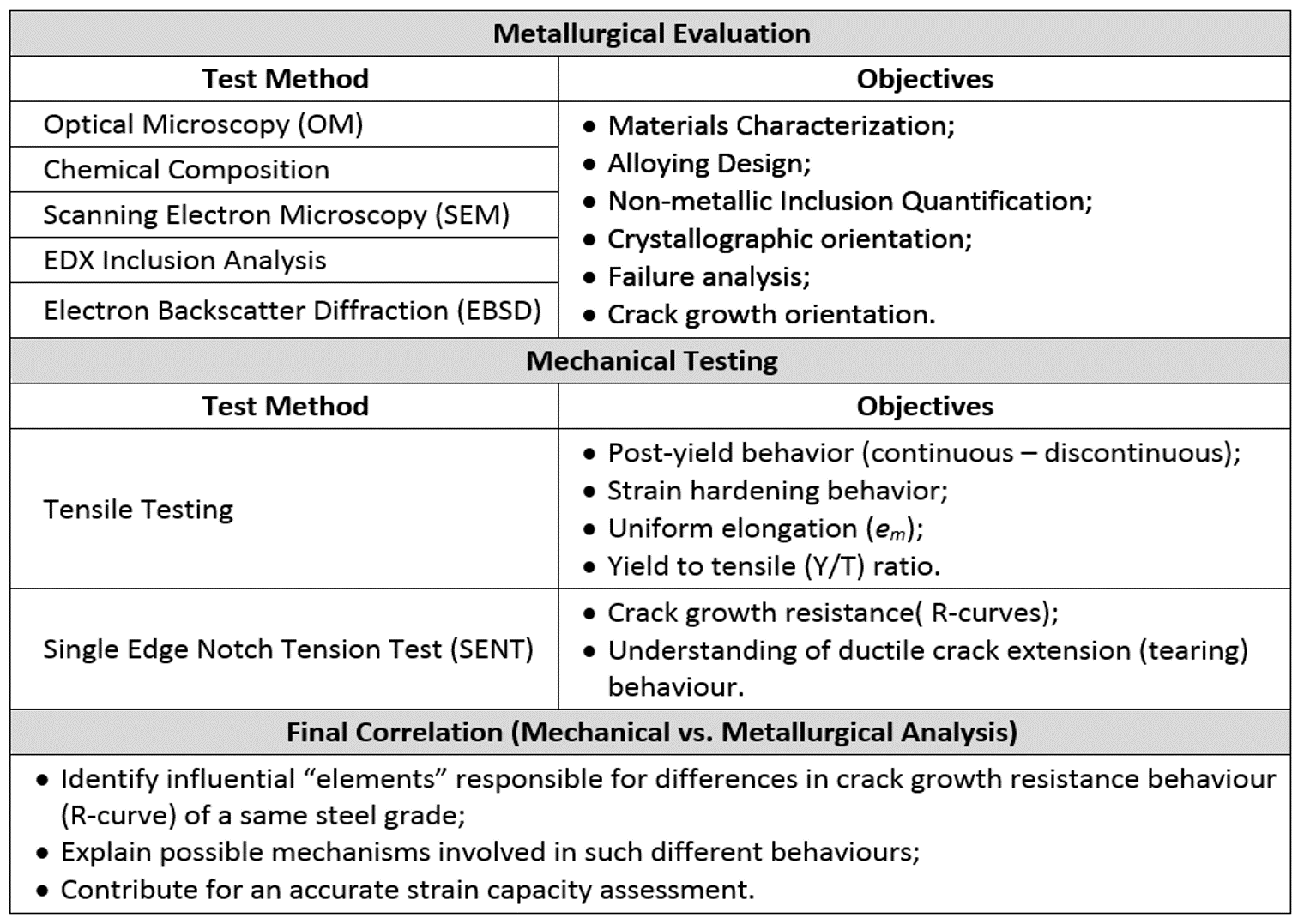

The research ambitions as well as the relevance of this study in a strain-based design framework are both presented below:

Thus, to achieve these objectives it is necessary an interdisciplinary approach between mechanical and metallurgical engineering fields to enhance research capacity. The required knowledge regarding mechanical engineering aspects is mostly provided by methodologies developed and established by LABO SOETE, while the metallurgical understanding is the field of expertise of this researcher.