Hybrid nanofibrous membranes with superior properties for advanced wound dressings

Creating the ideal environment for improved healing using nanofibers

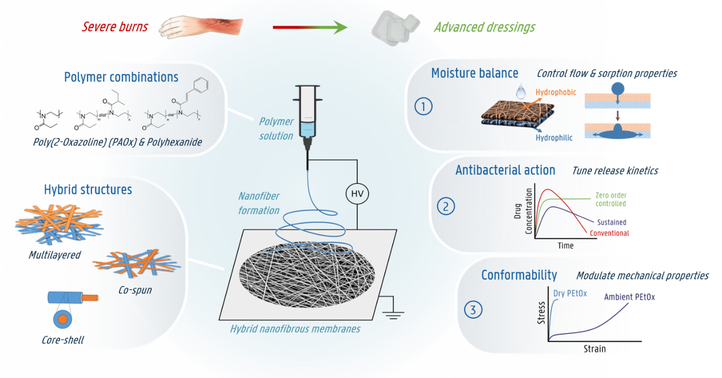

As severe burns are a leading cause of morbidity, proper wound care is crucial. Treating burns requires specific care to provide an infection-free and moist environment. As such, advanced dressings are essential, however, no all-round dressings for every burn exist and the demand remains pressing. Our aim is to innovate novel wound dressings by combining both moisture regulation, antimicrobial action and conformability in one single, nanofibrous dressing.

Did you know that every year there are around 10.000 building fires causing numerous victims in Belgium alone? Or that globally more than a million hospitalisations due to extreme burns are reported each year? With these numbers, burn wounds are an obvious leading cause of morbidity. Even more so, these initially non-fatal wounds account for around 180.000 deaths annually due to complications during the healing process. Mostly, infections taking place at the wound site are to blame, as burns suffer from a high risk of infection due to the pathophysiological circumstances of the wound. These losses can be avoided by proper treatment, for which the use of advanced dressings that provide an optimal healing environment is crucial. As such, the wound must be kept moist – but not wet – to ensure rapid healing, while infection must be prevented and managed, and no additional shear is transferred to the wound. Moreover, the dressing must be breathable, non-cytotoxic, easily removable, and be available in different shapes and sizes. Although several multipurpose dressings have been successfully developed, the demand for an all-round wound dressing remains pressing.

Recently, polymeric nanofibrous membranes are being put forward for next-level wound dressings. This because of their unique set of properties, such as an extremely high porosity, large specific surface area and inherent flexibility. Combined with their versatile and “green” production via solvent electrospinning, which allows for drug doping and the creation of hybrid structures, they make a perfect candidate for this application.

Of course, polymer selection is vital for nanofibers that will be in contact with the human body. One polymer class that is particularly interesting for this consists of the novel poly(2-alkyl/aryl-2-oxazoline)s (PAOx). They are biocompatible, exhibit a rich structural variety, allowing for control of the hydrophilicity of the resulting polymeric material, and are processable from green solvents. As such, it is believed that moisture management can be achieved by the exploitation of a selection of PAOx, when combined in hybrid nanofibrous structures. For instance, a multi-layered membrane consisting of a hydrophobic layer combined with a hydrophilic layer is able to transport moisture directionally in a controlled way. Investigating which PAOx combinations are stable enough in watery environments and how they can be used in hybrid nanofibrous structures for moisture management is the first focus point of this research.

As a moist environment increases the risk of microbial infection, the dressing is required to provide an adequate antimicrobial response. For this, incorporation of an antimicrobial agent in the dressing, which is released during the dressing’s lifetime on the wound, is the most promising option. In this research’ second focus point, polyhexanide (PHMB) is opted for, as it is recently put forward as the antimicrobial of choice for burns. Of course, the agent’s release must occur in a controlled way to provide the right therapeutic drug concentration in the wound bed at all times: a too low concentration results in limited efficacy of the antimicrobial, while too high concentrations can be toxic. For this, hybrid structures such as core-shell nanofibers and multi-layered membranes from PAOx polymers combined with PHMB are explored.

Finally, the mechanical performance of the prepared membranes is to be examined as it is intertwined with the healing efficiency and patient comfort. For instance, dressings applied to joint areas should be adequately flexible, while still providing the optimal healing environment. In general, materials will behave differently in moist conditions, e.g. being more flexible when moist. As a result, the third focus point of this research consists of examining these mechanical effects in PAOx nanofibrous membranes.

Acknowledgements

This research is funded by an FWO SB grant (1S22722N) and is performed at the Centre for Textile Science and Engineering by ir. Olmo Frateur in collaboration with the Supramolecular Chemistry group, the Laboratory for Pharmaceutical Technology and the Burn Wound Centre, all at Ghent University.

Contact

Prof. dr. ir. Karen De Clerck (Karen.DeClerck@UGent.be)