Robustness of steel reinforced glass systems with adhesive connections

Researchers:

- Mirko Pejatovic

- Jan Belis (supervisor)

- Robby Caspeele (supervisor)

Description:

Architectural contemporary trends sometimes require very high level of structural transparency, which typically can be realized using (structural) glass. However, sufficient structural safety and robustness are required by modern building codes at both structural component and system level. Recent experiments on statically indeterminate steel reinforced glass beams have shown that system action can be achieved through plastic hinge formation and stress redistribution. Additional system safety and robustness can be provided through the activation of membrane action in a member in case of semi-rigid interaction with its supporting structural elements. However, previous experiments have treated restraining effects as rigid, which is not the case in realistic structural systems.

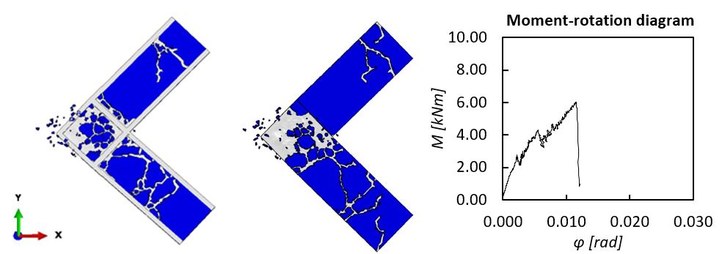

A vast majority of joints behave in a semi-rigid way (e.g. steel reinforced glass beam-to-column adhesive connections). The stiffness of restraints has an important influence on the ultimate load-carrying capacity in case of membrane action. A less rigid horizontal restraint, for instance, may lead to a reduced ultimate capacity. This is the reason why reliable models that take into account restraint stiffness are necessary for the prediction of membrane action in restrained glass components.

Traditional mechanical joints in glass raised safety concerns due to introduction of microcracks and residual stresses. They contain discontinuities that induce stress concentration which may lead to premature failure. To avoid these issues, adhesive connection techniques can be used. They provide more efficient and smoother transmission of high shear effects among connection components. Knowledge about rotational characteristics of such connections is important in order to be incorporated in a robust structural system.