Leadership in enabling and industrial technologies-SPIRE-CIRMET

Introduction

Innovative and efficient solution, based on modular, versatile, smart process units for energy and resource flexibility in highly energy intensive processes

15 partners

Coordinator:

Fundacion Tecnalia Research & Innovation

San Sebastian, Spain

Duration: 42 months

Description

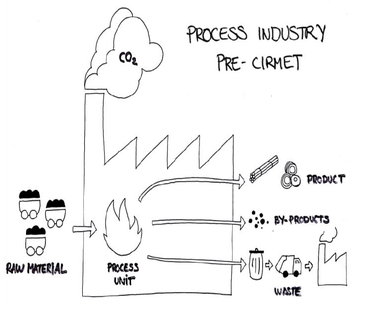

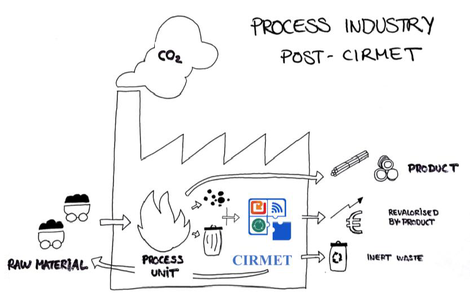

The project aims to design, develop and validate an innovative solution, the CIRMET solution, to provide energy and resource flexibility to Energy Intensive Industries (EIIs).The CIRMET solution will be validated in an operational environment (TRL7) in an existing process plant (non-ferrous sector) while the replicability of the solution will be assessed in three additional energy intensive sectors (steel, cement and water sector). For this purpose, three new demonstrators will be build up, plus the retrofitting of existing industry process unit. The new demonstrators or modules will be: EFFIMELT furnace, a new concept of flexible and modular process unit for industrial wastes treatment, RECUWASTE heat recovery unit, for flue gas heat recovery and transformation into compressed air to reused in the same plant, having also the possibility of storing the excess energy and AFF40 (Analytic For Factory 4.0) platform, to improve process plant competitiveness, to increase energy and resource efficiency by controlling and optimizing process units. The retrofitting of an existing process unit (Metallo S.L process furnace) will be done to implement and validate the complete CIRMET solution.

A well-balanced consortium formed by academia, research organization, SMEs and energy intensive industries ensures the whole value chain needed to achieve project objectives and paves the way for future exploitation of the solution. The effective dissemination of project outcomes to the current and next generation of citizen and employees through the development of learning resources with flexible usage to be carried out by education/training experts within the consortium is eventually also an important objective of the consortium.

Objectives

These are the objectives of CIRMET:

The main objective of the project is to develop and validate an innovative and efficient solution to the energy intensive process industries for energy and resource flexibility, the CIRMET solution.

The CIRMET solution is based on modular, versatile and smart process units for energy and resource flexibility. It allows processing within the same plant raw material, by-products and wastes. It is also adapted to use recovered and sustainable energy supply. And finally, it is worth mentioning that the CIRMET solution, is controlled and optimized through an advanced data analytic platform (Figure 3).

The project aims to validate the CIRMET solution in an operational industrial environment and for this purpose it is proposed to build up 3 new demonstrators/modules;

• EFFIMELT furnace, a new concept of flexible and modular metallurgic furnace for the processing of industrial metallic wastes. It can be integrated in any process unit of Energy Intensive Industries (EIIs) with the idea of providing a second life to their wastes, as after being treated in this unit, they can be a new feedstock for original core process and valuable feed product for other process units.

• RECUWASTE heat recovery unit, for flue gas heat recovery and transformation into compressed air to be used in the same plant through an innovative continuous variable transmission (CVT) concept that will permit to adapt the power generated with the demons of compressed air, having also the possibility of storing the excess energy in a mechanical device.

• AFF40 (Analytic For Factory 4.0) platform, addressing the main motivations industry faces: improve process plant competitiveness, by ensuring the best mix between raw materials and by-products to maximize final product repeatability and waste re-valorization, increase resource use efficiency by controlling and optimizing process units and finally to raise awareness of resource use efficiency of the process units.

and,

• retrofitting of an existing process unit (METALLO´s metallurgy furnace) implement and validate the complete CIRMET solution.

Role of Ghent University

UGENT will translate the results of this project in a highly modular set of short online training modules. By using insights from online pedagogy and instructional design, each module will be developed as a self-contained microlearning block, that engages the learner and brings one idea (or project result) across. Universities that want to offer a course on these topics, can use this structured set of modules (or parts thereof) as the basis for a blended learning course. A group of basic modules will be foreseen that offers the minimally required background for people entering from different fields. All modules will be developed in a low-budget way and will be offered on a platform where they can live with minimal maintenance. In this way, they can serve long beyond the duration of this project.

Website

Contact

Prof. Stefaan Cottenier

Department of Electrical Energy, Metals, Mechanical Constructions and Systems &

Center for Molecular Modeling (CMM)

Phone number: 09 264 65 36

E-mail