Interreg France-Wallonie-Vlaanderen - 3D4MED

Introduction

Development of personalized 3D implants in new shape-memory polymer materials to improve patient care

After many years of technological development, 3D printing has shown its usefulness in the tissue engineering sector. Since the first prosthesis printed in 1999 or the first blood vessel in 2010, the range of applications enabled by this technology in combination with polymers is promising.

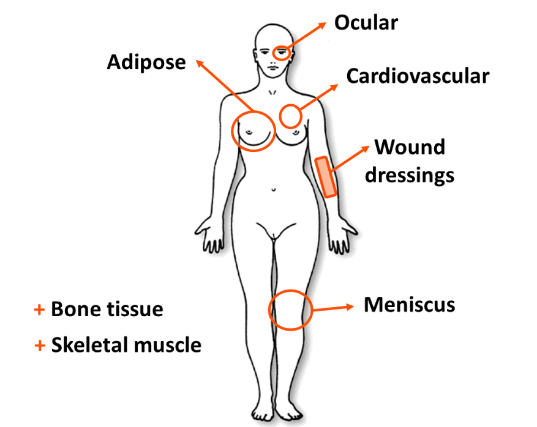

3D4MED’s objective is to develop innovative 3D matrices for tissue engineering in order to rebuild, regenerate or replace the function of defective tissues or organs. Innovation lies both on the preparation of individualized implants with complex geometry fostering cell colonization and tissue integration and the formulation of new biocompatible shape-memory polymers minimizing mechanical trauma and immune rejection during and after the implantation.

Project description

Context

The aging of the population leads to a growing need for new tissue repair technologies to substitute defect organs. Currently, tissue repair is performed either by autologous grafts or by transplantation from deceased donors causing problems related to immune rejection. In addition, the low availability of donor organs is no longer in line with the ever-increasing demand for tissues.

The main challenge of tissue engineering is to overcome the problems associated with organ shortage by providing surgeons with functional substitutes developed in vitro.

The principle is based on:

The personalized development of temporary polymer matrices with minimal inflammatory issues that would allow cell colonization within their architecture during degradation and trigger the formation of the target tissue;

The biocompatibility of the polymers used for tissue repair;

The structural characteristics (porosity/interconnectivity of pores) as well as the mechanical properties (elasticity/resistance) play a key role in cell development and tissue integration.

Consortium

To meet the needs of tissue engineering, 3D4Med is a collaboration constituting academic research groups, university hospitals and SMEs active in transdisciplinary research covering materials science, tissue engineering and medicine.

3D4Med gathers a cross-border partnership in the Interreg program France-Wallonia-Flanders which involves major stakeholders in the field that will work closely together with a focus on areas of personalized (bio)mechanical solutions with minimal inflammatory issues.

Innovation

In this context, the 3D4Med project will be able to create a solution through the knowledge of materials and 3D printing, developed starting from the expertise of the consortium partners.

Through tissue engineering, it becomes possible to create personalized tissues and organs, in the laboratory, based on autologous cells. The cells will thus be obtained from the patient, via a non-invasive technique, and integrated on support structures developed throughout the project.

With the support of 3D printing techniques, it becomes possible to develop patient-specific structures that will provide an exact mimic of the defect tissue to be replaced.

Objectives

3D4MED’s objective is to develop innovative 3D matrices for tissue engineering in order to rebuild, regenerate or replace the function of defect tissues or organs. Innovation lies both on the preparation of personalized implants with complex geometry fostering cell colonization and tissue integration and the synthesis of new biocompatible shape-memory polymers minimizing mechanical trauma and immune rejection during and after the implantation.

- The main objective of the project is to develop biodegradable shape-memory matrices combining structure and biologically active surfaces by 3D printing

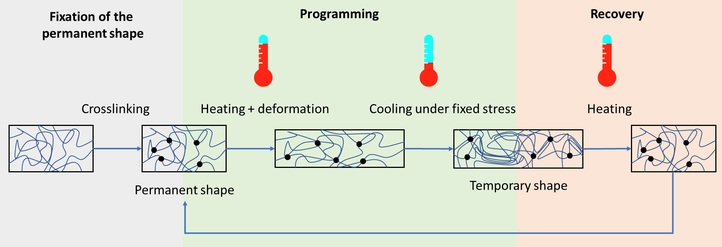

- The general concept is that the shape of shape-memory polymers can change after a stimulus such as temperature, pH, etc. In this project, shape-memory polymers are activated at 37°C (body temperature) to adjust their form to the defect tissue to be replaced.

- A minimally invasive surgical procedure can then be performed so that the implant will exhibit a reduced size before actuation. Biodegradable polymers with shape-memory properties will become resorbed over time to avoid any immune response issues or potential infection in the long term.

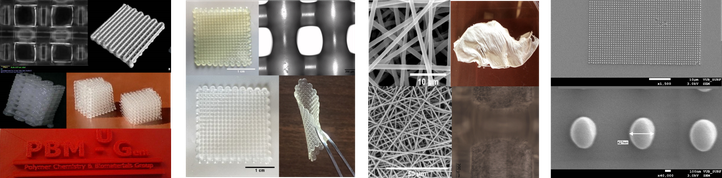

- 3D printing will make it possible to process these polymer matrices with complex and personalized geometry which are difficult to achieve by conventional techniques while developing objects in line with structural and mechanical requirements (porosity, rigidity…) required for tissue engineering.

Role of Ghent University

The Polymer Chemistry & Biomaterials group of UGent has great expertise in the development and characterization of functional polymers for different biomedical applications along with processing through electrospinning, 3D-printing and 2-photon polymerization.

With this knowledge/expertise in polymer synthesis, polymer processing and characterization, UGent/PBM is the leader of 3D4Med WP4: ‘Selection and development of biomaterials with shape-memory properties’. In addition, UGent will collaborate closely with other partners to complete WP5: ‘Development of complex medical implants by 3D-printing’ and to communicate the results via networking.

Dutch summary

Ontwikkeling van gepersonaliseerde 3D-implantaten in nieuwe vormgeheugen-polymeermaterialen teneinde de patiëntenzorg te verbeteren.

Na vele jaren van technologische ontwikkeling heeft 3D-printing zijn nut bewezen in de weefselregeneratiesector. Sinds de eerste prothese die in 1999 werd geprint of het eerste bloedvat in 2010, is de waaier van toepassingen die deze verwerkingstechniek in combinatie met polymeren mogelijk maakt, veelbelovend.

Het doel van 3D4MED is de ontwikkeling van innovatieve 3D-draagstructuren voor weefselregeneratie teneinde de functie van defecte weefsels of organen te reconstrueren, te regenereren of te vervangen. Innovatie ligt zowel in de ontwikkeling van gepersonaliseerde implantaten met een complexe geometrie die cel-kolonisatie en weefselintegratie bevorderen en de synthese van nieuwe biocompatibele polymeren met vormgevingsgeheugeneigenschappen die mechanische trauma's en een immuunrespons tijdens en na de implantatie minimaliseren.

French summary

Développement d’implants 3D individualisés dans de nouveaux matériaux polymères à mémoire de forme pour améliorer le soin des patients

Après plusieurs années de développement technologique, l’impression 3D a pu montrer son intérêt dans le domaine de l’ingénierie tissulaire. Entre la première prothèse imprimée en 1999 ou encore le premier vaisseau sanguin en 2010, l’éventail d’applications ouvertes par ce nouvel outil de mise en oeuvre dans le domaine des polymères est immense. Cependant, il reste toujours conditionné à la levée de verrous technologiques liés aux matériaux, interfaces et procédés.

L’objectif de 3D4MED est de développer des matrices 3D innovantes pour l’ingénierie tissulaire dans le but de reconstruire, régénérer ou remplacer la fonction de tissus ou d’organes déficients. L’innovation réside à la fois dans la préparation d’implants individualisés à géométrie complexe favorisant la recolonisation cellulaire et l'intégration tissulaire mais aussi dans la formulation de nouveaux polymères biocompatibles à mémoire de forme minimisant le traumatisme mécanique et le rejet immunitaire pendant et après implantation.

Website

Contact

Prof. Sandra Van Vlierberghe

Polymer Chemistry & Biomaterials Group

Centre of Macromolecular Chemistry

Department of Organic and Macromolecular Chemistry

Phone number: +32(0)9/264.45.08

E-mail