Geert De Schutter - SmartCast

He graduated as Master of Science in Civil Engineering in 1990, and obtained his doctoral degree in Civil Engineering in 1996.

He is laureate of several national and international awards, among which the Vreedenburgh Award in 1998, the RILEM Robert L’Hermite Medal in 2001, and the ACI Anderson Medal in 2014.

During his career, he has been invited professor at several universities: 2002 Oita University, Japan; 2008-2014 University of Cergy-Pontoise, France; 2014-2017 Tongji University, Shanghai, China; 2016 University of Nantes, France. In 2012, he was awarded the Francqui Chair at the University of Liège, Belgium.

Prof. De Schutter is active member of RILEM, ACI and fib. From February 2009 to February 2014, he was also Director of Development of RILEM. At present, he is still member of RILEM Bureau, and is chairman of RILEM Development Advisory Committee (DAC). He was named RILEM Fellow in 2015.

Contact: Geert.DeSchutter@UGent.be

Publications: https://biblio.ugent.be/person/801000826173

Smart casting of concrete structures by active control of rheology (SmartCast)

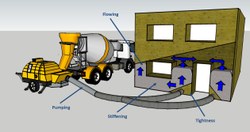

Concrete production processes do not take full advantage of the rheological potential of fresh cementitious materials, and are still largely labour-driven and sensitive to the human factor. SmartCast proposes a new concrete casting concept to transform the concrete industry into a highly automated technological industry. Currently, the rheological properties of the concrete are defined by mix design and mixing procedure without any further active adjustment during casting. The goal of this proposal is the active control of concrete rheology during casting, and the active triggering of early stiffening of the concrete as soon as it is put in place. The ground-breaking idea to achieve this goal, is to develop concrete with actively controllable rheology by adding admixtures responsive to externally activated electromagnetic frequencies. Inter-disciplinary insights are important to achieve these goals, including inputs from concrete technology, polymer science, electrochemistry, rheology and computational fluid dynamics.

Work plan

In the short term, achieving the active control of the pumping slip layer will have an immediate impact on concrete industry, as this can be applied on pump trucks without interfering with the elements to be cast. In the longer term, making possible concrete casting with active control of flow and stiffening will be a totally new paradigm for concrete industry. Moving from ‘passively’ relying on evolving properties of fresh concrete, to ‘actively’ controlling rheology and stiffening will revolutionize concrete industry and bring quality levels to higher standards. The developed active rheology control will also provide a fundamental basis for the development of future-proof 3D printing techniques in concrete industry. For society, it will mean more reliable construction, with less damage cases and less failures, while better preserving the environment (reduced carbon footprint, reduced noise and vibration levels, reduced exposure of technicians to safety and health risks).