Test & Research Infrastructure

Discover NaMiFab’s state-of-the-art infrastructure for nano- and microfabrication, enabling research and testing across multiple domains.

Cleanroom

The equipment for fabrication and characterization at the nano- and micrometer scale is located in the Ghent University cleanroom building at campus Ardoyen.

The cleanroom is an environment where we limit the presence of sub-micron particles and control other factors such as temperature and humidity. This is necessary to achieve sound manufacturing processes that ensure reproducible results.

Equipment for lithography (pattern definition)

EVG 620 double-sided mask aligner

The mask aligner is used to transfer a pattern to a photosensitive material by selective exposure (through a mask) to a UV radiation source. The equipment supports several modes (proximity, soft / hard / vacuum contact) and can also do bottom side alignment. It can also be used in nano-imprint mode, where the pattern is transferred by imprinting.

Equipment for layer deposition

Equipment for material structuring

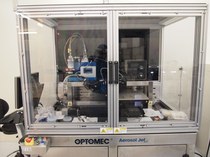

3D Micromac microSTRUCT vario ps/fs Laser setup

Pico- and femtosecond laser setup ideally suited for laser structuring, cutting, drilling and welding applications on a variety of substrates, e.g. metals, semiconductors, alloys, transparent and biological material, ceramics and thin film compound systems. The setup is equipped with following lasers: femtosecond pulse laser at 1030.5 nm; picosecond pulse laser at 1064 nm, 532 nm and 355 nm

Equipment for etching

Equipment for inspection

FEI Nova 600 Nanolab Dual-Beam FIB-SEM

SEM (Scanning Electron Microscope) can be used for inspection of samples with resolution down to nanometer scale. The FIB (Focused Ion Beam) column can be used for making cross-sections in virtually any material and gives the option to look "into" the material. FIB also allows to directly pattern materials with nanometer resolution. Options include electron backscatter diffraction (EBSD, for evaluation of microstructure of material), several etch gas injectors, Auto-slice&View and nanomanipulators for TEM-slice preparation.

Equipment for assembly

K&S Manual Wedge Bonder model 4523

Manual wedge bonding of:

- aluminium wire: 18 μm and 32 μm, 30/45deg and deep access wedges.

- gold wire: 38 μm (deep access) and 76.2x25.4 ribbon (deep access).

This model offers the versatility to bond simple discrete devices, chip on board, up to complex hybrid, microwave devices. A bonding head with a deep access option and tail adjust system supports deep cavity microwave applications where tight control over the tail length is essential. With the small 18um wire capability the creation of short wires with low loops to support RF devices is possible. A manual Z mode allows operator control over looping and wire length, providing excellent results for tight spaces or unusual loop requirements.

Liquid crystal device assembly

Several devices for assembly of liquid crystal devices including spin coater, dip coater, Asymtek Dispensemate, Oxford Instruments rubbing machine, UV OmniCure UV illumination, several ovens (including high temperature annealing oven), temperature controlled vacuum filling equipment, inspection microscope.