Tribology, fracture and fatigue lab

Their work blends advanced experimental setups with high‑fidelity numerical modeling (e.g., Finite Element Analysis). The lab provides industrial services in component design, material characterisation, testing and consultancy.

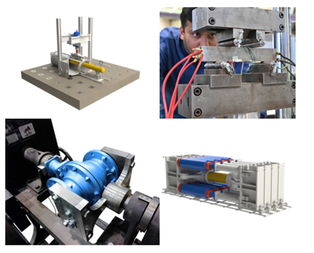

Component and structural testing

Offshore wind components (foundations, towers, blades, joints, etc.) face extreme environments: cyclic loads from wind and waves, high pressures, fatigue, corrosion, etc. The testing equipment at Soete lets you simulate, measure, and qualify how materials, components, and full-scale structures behave under these real-world stresses — reducing risk, ensuring safety, and improving design.

Key test equipment & capabilities at Soete relevant to offshore wind:

| Facility/Equipment | Key Capabilities & Specifications | Why it's important for offshore wind |

|---|---|---|

| Universal multipurpose test rigs up to ~2,500 kN | Can do tensile, bending, fatigue, welded component tests etc. | Turbine towers, foundations, joints: need to withstand large static & dynamic loads; welded joints are critical points. |

| Bespoke test setup up to ~8,000 kN | Very large static load capacity; for large components or assemblies. | Large components (e.g. monopile sections, large joint welds, large structural parts) need to be verified under extreme loads. |

| Full-scale 4-point bend setup of pipes (OD ~400 mm, internal pressure ~64 bar) | Tests large pipes under bending and internal pressure. | Offshore structures often use large tubular members (transition pieces, suction buckets, piping for cable protection), subject to internal pressures and bending from waves & currents. |

| 4-point bending test equipment (beams/girders etc.) | Applies bending loads to beams/girders. | Blade root flanges, girder supports, flange joints, tower segments experience bending; fatigue life under bending is crucial. |

| Large scale thrust bearing test setup | Tests axial/radial loads in thrust bearings; friction, wear, load capacity. | Turbine thrust bearings (in the main bearing), yaw systems, pitch systems — all need reliable, durable bearing behavior under heavy loads and cyclic/tidal motion. |

| Torque test setup | Torsional loading. | Gearboxes, shaft couplings, turbine shaft, drive trains need to be able to handle torque and cyclic torsional stress. |

| DIC Measuring System (Digital Image Correlation / Tracking) |

Non-contact 2D/3D optical deformation/strain measurement; tracks crack initiation, displacement, strain fields. | Useful in validating models of deformation under load; predictive of crack growth; ensures structural integrity of non-standard geometries or welds. |

| Charpy test setup |

Impact toughness; behavior at brittle vs ductile transition (often at low temperatures). | Offshore environments can be cold; structural steels must remain tough at low temperatures; risk of brittle fracture is a real concern. |

| Pressure testing services |

Testing pressure components (pipes, vessels) under internal pressures. | Offshore use of pressurized systems (hydraulics, sealed joints, cable conduits) means these components must be validated for pressure conditions + mechanical loads. |

| Material testing (non-destructive and destructive for metals & non-metals) |

Tensile tests, hardness, toughness, etc.; also likely fatigue, fracture toughness. | Material selection & qualification is vital (steel, composites, coatings) to ensure strength, fatigue life, corrosion resistance. |

| Simulations & Failure Analyses (supporting) |

Modelling (finite element, etc.), analysing how failures might occur. | Helps predict lifespan, optimise design, reduce over-engineering, and avoid unexpected failures during operation. |

Friction and wear

Here are the main friction & wear-related test services particularly useful for offshore wind, along with their capabilities:

| Facility/Equipment | Key Capabilities & Specifications | Why it's important for offshore wind |

|---|---|---|

|

Small scale tribometers (pin-on-disk, high temperature etc.) |

Tests friction and wear under defined loads, speeds, temperatures on small samples. |

Useful for comparing coatings, lubricants, material pairings for moving parts (e.g. pitch/yaw bearing interfaces, gear teeth); high temperature behaviour in nacelle etc. |

|

Large scale flat-on-flat tribometers |

Larger contact areas; more representative of “real-world” surfaces. |

Surfaces like large bearing flanges, pivots etc. are large; small sample tests may not scale; flat-on-flat provides more realistic conditions. |

|

Back-to-back gear tester (FZG) |

Tests gears under controlled load, speed, lubrication; standard in gear qualification. |

Gearboxes in wind turbines are critical, often fail due to wear, misalignment, lubrication issues; qualification and wear testing ensures reliability. |

|

Large scale bearing test setup |

Tests large bearings under boundary or dry friction regimes; wear, load, lubrication behavior. |

Pitch / yaw / main bearings are large; they must tolerate edge cases (e.g. low lubrication, high load), misalignments, start-stop cycles. |

|

Shackle chain wear test-rig & Conveyor chain wear test-rig |

Wear testing for chains or components under repetitive contact /drag /sliding. |

Mooring chains, cable anchoring, or drag-chains for foundation installation, or moving parts may see similar wear modes; validating wear life is important. |

|

Universal mechanical tester - tribology |

More general capability: friction, wear, coating performance, etc. |

For validating protective coatings, bearings lubrication regimes, friction reduction measures, maintenance intervals. |

|

Surface & form measurement / Optical profilometry (Keyence VR 5200; Taylor Hobson CCI HD etc.) |

Non-contact 3D measurements of form, surface roughness, topography, defects. |

Surface finish affects friction, fatigue crack initiation; corrosion pits etc. can degrade surfaces; precise measurements are needed for quality control and wear prediction. |

|

Hardness testing (e.g. LECO hardness tester) |

Measures hardness, which correlates with wear resistance, strength; can check heat treatments etc. |

Hardened steel parts (bearing races, gears) need adequate hardness; offshore wear & impact demands robust materials. |