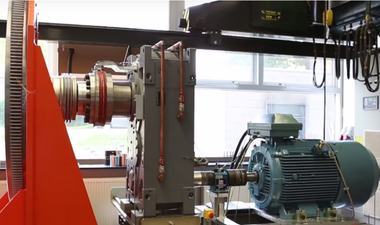

Test Rig for Energy-Efficient Electric Drivetrains & Components

Offshore wind turbines often use permanent magnet synchronous generators (PMSGs) or direct-drive systems to reduce mechanical complexity and maintenance needs. The UGent test rig supports testing high-torque, low-speed electric machines—ideal for simulating offshore wind turbine generators.

It can mimic realistic offshore load cycles using Hardware-in-the-Loop (HIL), including variable wind speeds and grid interactions. Drivetrain efficiency can be measured with a calorimeter and thermal cameras allowing for precise loss quantification and thermal mapping, helping engineers design more efficient, longer-lasting components. The test bench supports integrated testing of electric machines with converters, enabling system-level optimisation for energy yield and grid compliance. This test infrastructure can simulate unsteady torque and dynamic pitch/load—crucial for drivetrain components in floating applications.