High-speed electrical machines

High-speed machines combine excellent efficiency with a low weight, they are therefore ideal candidates for future improvements of a wide range of applications.

Modern society undergoes an increasing ecological awareness, this awareness is translated to the industry as a trend towards higher efficiency. Moreover, in mobile applications weight reduction has become very important to reduce transportation energy.

One possibility to meet these new demands is to operate electrical machines at very high speeds. Indeed, in applications that require high rotational speeds, such as milling machines, using a high-speed electrical machine avoids the need for a gear box. Which means a significant loss reduction. Moreover, when the rotational speed is increased the machine’s torque decreases at a fixed power. Typically, this means that the machine’s dimensions can be decreased, resulting in a weight reduction.

However, when designing high-speed electrical machines, one has to cope with some fundamentally different problems in comparison with classical machine design.

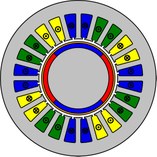

At Ghent University, the research on high-speed electrical machines focusses on the electromagnetic modelling of the machines. This is done via analytical subdomain methods and finite elements. The topology is usually a permanent magnet synchronous machine with surface magnets.

This allows to gain a better understanding of the physical effects related to high-speed operation. On the practical side, the lab has developed a test setup to evaluate the effect of different control strategies on high-speed PMSMs.