Magnetic materials for high-speed electrical machines

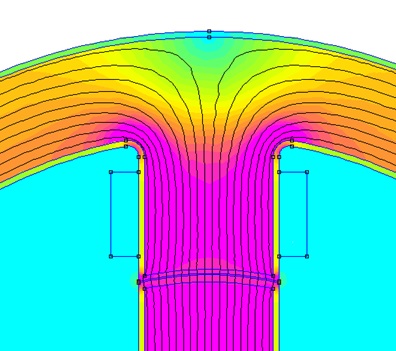

This project investigates the influence of motor construction on iron loss using electromagnetic and magnetomechanical models, including the aspects leading to magnetic material degradation, e.g. cutting or punching of laminations, glueing and bending of laminations, radial and axial pressure on the stack, interlocking and stacking shape. The focus is on high-speed, high efficiency machines because a good understanding of iron loss is crucial for such machines.

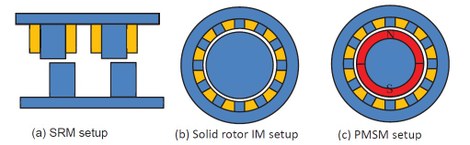

This research subject addresses an important problem for the future development of high-performance rotating systems, i.e., development of accurate loss calculation methods, which are also characterized by high dynamic performance, high power density and high efficiency. This loss model under development is expected to have a major impact in many high-speed applications where improving power density and safety plays an important role, such as electric and hybrid vehicles, combined heat and power systems, process industries, mining, oil and gas, smart grids, and, in a longer run, low-cost electric drives. The analysis and verification of both the micro- and macro sides of the magnetomechanical influences is expected to significantly improve the efficiency, hence increase the productivity, energy efficiency, safety and profitability of the involved businesses. The outcome of this research is a generalised model for calculating iron losses for high speed solid rotor induction machines (IM), high speed switched reluctance machines (SRM), and high speed permanent magnet synchronous machines (PMSM) considering arbitrary (rotating) waveforms. This allows to account for the construction and stacking technique details that may lead to material degradation, i.e. cutting effects, glueing and bending, radial & axial pressure, interlocking and lamination stacking shape. The electrical excitation of the pre-prototype setups will include realistic waveforms for IM and SRM, possibly including PWM, and sufficiently high electrical frequencies to be representative for high speed machines.