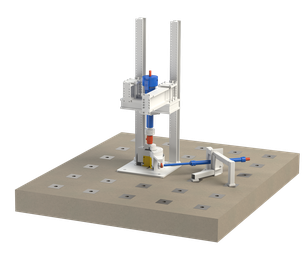

Large scale thrust bearing test setup

Features

This test-rig is designed by the Laboratory Soete to investigate the friction and wear behavior of axial thrust washers, more particularly pintle bearings. Beside pintle bearings, thrust and axial bearings can also be tested. The test-rig can accommodate bearings with diameters up to 400 mm. The bearing material can be flat or spherical.

Due to the chamber of the test-rig in which the bearing material is placed, real operating conditions of the bearings (grease, water lubrication, sea water ingress, dirt etc.) can be simulated.

The test-rig is servo-hydraulically operated which allows for a load controlled or displacement controlled operation to ensure an accurate execution of the test. The test rig is equipped with data acquisition devices to measure various additional instruments such as temperatures, local displacements, local strains, …

The Counter material (pin) is bolted to the bottom plate of the test-rig and remains stationary when testing. The bearing material is loaded through a self-aligning roller thrust bearing and driven by a lever arm connected to a hydraulic actuator. This arrangement allows the thrust bearing to align its self with the counter material (pin) and to move freely in the radial direction during the test.