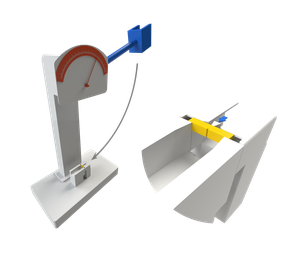

Charpy test setup

Features:

- In-house machined samples in accordance with standard ASTM A370:

- Standard dimensions: 55 mm x 10 mm x 10 mm

- Minimum dimensions: 55 mm x 10 mm x 2.5 mm

- Common practice V-notch, but also U-shaped, keyway… notches are possible

- Impact energy up to 400 J

- Testing temperatures ranging from -20 °C to 20 °C.

Application:

- Determine toughness of metals, plastics and composites.

- Impact testing at different temperatures to capture ductile-to-brittle behaviour.

- Girth weld analysis with notch applied in weld metal center (WMC), heat-affected-zone (HAZ) and base material (BM).

- Three repeat tests are conducted for every configuration (temperature, notch location and orientation) in order to have statistically sound results.

Working principle:

A Charpy impact test is a dynamic test in which a notched specimen is struck and broken by a single blow of a freely swinging pendulum. The difference in height of the upward swing of the pendulum is used to determine the absorbed energy in the fracture event.

Reported data:

For each specimen, the following data is reported:

- the specimen thickness [mm];

- the net cross sectional area, An [mm²];

- the test temperature [°C];

- the absorbed Charpy V impact energy [J];

- the percentage shear fracture [%], determined following ASTM E 23;

- the lateral expansion [mm], determined following ASTM E 23.