Material Testing Services

Material testing is crucial if you need to confirm material properties to examine failures, enhance innovative materials, ensure material properties for certain applications, carry out fundamental research on the material’s theoretical strength…

Tensile testing

Manufacturers, product developers or users benefit in terms of safety and integrity management knowing the tensile properties of base and joining materials. Tensile testing is a widely used destructive, mechanical test in which the material is subjected to a uniaxial tension load up until failure. This test method is used to determine the strength of the material as well as how far it can be strained before breaking.

WHY USE TENSILE TESTING SERVICES FROM SOETE LABORATORY?

- Standard tensile testing according to ISO 6892

- Other tensile test standards possible upon request

- Load capacity up to 8000 kN

- Adjustable to perform non-standardized tests

Hardness testing

Hardness is an important measure to evaluate the suitability of a material or material treatment for the required application. Material and surface properties, including strength and wear resistance, may be assessed by means of hardness testing.

Increased strength of a weld and increased wear resistance of materials subjected to friction or erosion are only a few examples in which increased hardness is preferred.

WHY CHOOSE HARDNESS TESTING SERVICES FROM SOETE LABORATORY?

- Detailed Vickers hardness mapping

- Easy targeting of interesting zones

- Clear visualization

- Interpretation of the results

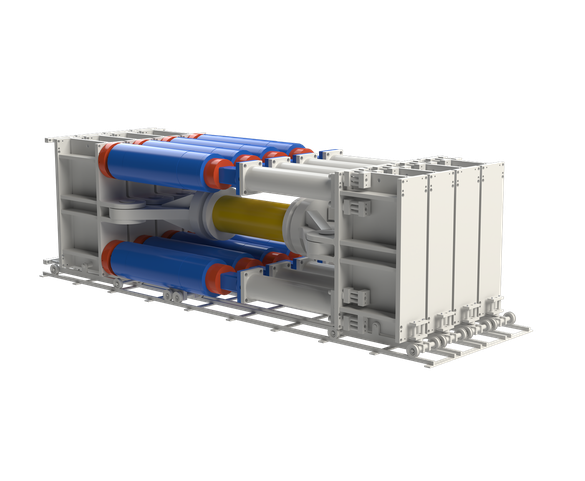

Custom made test rigs

One of Laboratory Soete’s highlights is the ability to subject large (even full-scale) components and structures to mechanical tests in near operational conditions.

WHY CHOOSE CUSTOM MADE FROM SOETE LABORATORY?

- We transform problems in solutions

- High capacity and full-scale possibilities

- Simulating real-world scenarios

- Provide lab services throughout the project lifecycle

Fracture toughness testing

Unpredictable, brittle failure of steel structures is very dangerous since it happens without warning. The objective of a fracture toughness test is to quantify the material’s resistance to crack propagation by measuring the energy needed to generate brittle and/or ductile crack extension. Fracture toughness is one of the most crucial properties to prevent material failure, which could lead to significant losses and unsafe situations.

WHY USE TOUGHNESS TESTING FROM SOETE LABORATORY?

- Standard in-house machined samples

- Different temperatures to capture ductile to brittle transition

- Applications: metals, plastics, composites, welds

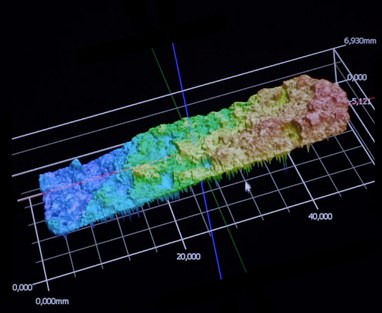

Surface profile characterization

Surface topography measurement can be part of quality management, since the topography may affect several operation characteristics of your component including friction, sealing and heat transfer. The surface structure is typically already formed during the manufacturing process, but may be changed during service life by for instance wear.

WHY USE SURFACE PROFILE CHARACTERIZATION SERVICES FROM SOETE LABORATORY?

- (non-)contact roughness measurements

- Detailed 3D scanning and measuring of surface degradation

- High quality 3D scan and geometrical analysis of components