Polyforce

Overcoming the material barrier for Selective Laser Sintering: research in novel processing techniques for the production of polymer microspheres as build material for powder bed fusion additive manufacturing.

What is it about?

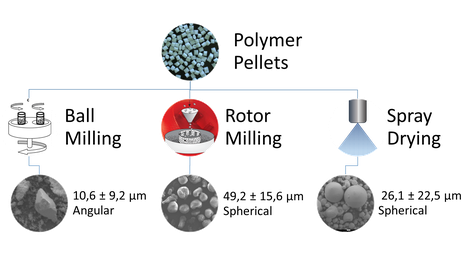

Selective Laser Sintering is a versatile 3D printing method in which a complex 3D product is sintered out of a polymer powder bed. The powders need to be predominantly spherical in order to exhibit free flowing behavior and have a mean diameter in the range of 45-90 µm. Today, the lion share of the materials available for SLS consist of PA materials or blends using PA materials.

Objective of the research

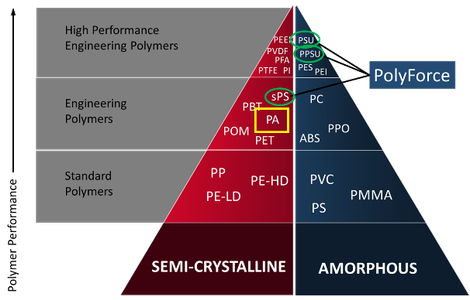

Nicolas Mys’ research topic consists in expanding this material palette by investigating new processing methods to develop microspheres from polymer materials exhibiting better intrinsic properties than the currently available materials. As the conventional methods used in industry are not economical and often result in bad morphologies and loss of intrinsic properties other methods need to be found. Both mechanical and physicochemical methods are investigated of which Rotor Milling and Spray Drying yield the best results. All produced powders are tested on change in their extrinsic and intrinsic properties by a variation of characterization methods using SEM microscopy, XRD, DSC, TGA, FTIR, CHNS analysis and Hausner ratio measurement to have an indication of powder flow. In a later stage the samples are used for actual sinter experiments in collaboration with KU Leuven.

Another way to expand the material palette is the use of blends, in this regard polysulfone-montmorillonite blends are tested using twin screw extrusion for melt intercalation. The used nanoclays are functionalized for better compatibilization with the polysulfone chains by grafting a phenylsulfone group on the nanoclay interface. These blends are tested for intercalation using XRD analysis, tensile tests and flame retardancy tests are performed to investigate the change of properties.

This research is part of an VLAIO funded project called PolyForce which works in collaboration with UGent, KU Leuven, Materialize and Solvay.

Key publications

Mys, Nicolas, An Verberckmoes, and Ludwig Cardon. “Spray Drying as a Processing Technique for Syndiotactic Polystyrene to Powder Form for Part Manufacturing Through Selective Laser Sintering.” JOM 69.3 (2017): 551–556.

Mys, Nicolas, An Verberckmoes, and Ludwig Cardon. “Processing of Syndiotactic Polystyrene to Microspheres for Part Manufacturing Through Selective Laser Sintering.” POLYMERS 8.11 (2016): 383–399.

Mys, Nicolas, Ruben Van de Sande, An Verberckmoes, et al. “Processing of Polysulfone to Free Flowing Powder by Mechanical Milling and Spray Drying Techniques for Use in Selective Laser Sintering.” POLYMERS 8.4 (2016): 150–166.

Type of funding and duration

VLAIO-SBO, 2013-2017

Contact

Coordinator: Prof. Ludwig Cardon