Hydrogen-material interaction

Hydrogen interaction with materials typically results in hydrogen assisted or hydrogen induced cracking or embrittlement.

It is well-documented that hydrogen has a detrimental effect on the mechanical properties of steels, especially on their ductility. This phenomenon is designated as hydrogen embrittlement or hydrogen induced cracking.

Even today, this phenomenon is not well understood. Moreover, hydrogen can still induce unpredictable failure of industrially relevant materials, although only a few ppms are present in the metal. Further investigation of the mechanisms that control this phenomenon is therefore essential.

High Strength Steels (HSS) are very prone to hydrogen related failure. Some steels show a ductility loss of 75% when charged with hydrogen! However, these materials are very interesting for the automotive industry and multiple structural applications due to their high strength/stiffness vs. weight ratio.

A detailed evaluation of the interaction between hydrogen and these steels is necessary to understand and predict potential hydrogen damage.

Study of the interactions between hydrogen, carbon and vacancies in iron-based alloys

Liese Vandewalle, in cooperation with SCK-CEN

The interaction of hydrogen with microstructural features can strongly influence the hydrogen embrittlement of a material. In this project, the interaction of hydrogen with vacancies, and clusters consisting of vacancies and carbon interstitials will be studied.

When steels are plastically deformed, rapidly quenched or irradiated, high concentrations of vacancies can be introduced in the material. These vacancies can group together and form clusters. Interstitials such as carbon and hydrogen, can bind to the vacancies, which results in a decrease of the vacancy formation energy as well as a decrease in vacancy diffusivity. Consequently, the vacancies are stabilized and higher vacancy concentrations can be reached. The strong binding of carbon atoms to vacancies gives also rise to the formation of a wide variety of carbon-vacancy complexes.

When hydrogen is introduced in steel, it can be trapped by the mono-vacancies, vacancy clusters and carbon-vacancy complexes. In addition, the presence of hydrogen during straining of the material promotes the formation and clustering of vacancies, resulting in a decrease of the resistance against ductile crack growth is reduced. Therefore, the interaction of hydrogen with vacancies and carbon atoms will be of large importance for the hydrogen embrittlement of most commercially used steels but especially for nuclear applications.

In order to study the hydrogen-carbon-vacancy interactions, a novel and innovative approach will be used in the present project. Complementary to the well-established methods for the evaluation of the hydrogen/material interaction, two advanced techniques, positron annihilation spectroscopy and internal friction, will be used. Additionally, since the vacancy concentration is higher at elevated temperatures, also gaseous charging of steels will be performed next to the conventional electrochemical charging.

Hydrogen induced damage in lightweight martensitic Fe-Al-C alloys

Margot Pinson

In a wide variety of industrial sectors there is a constant strife to obtain stronger and safer materials. In order to lower fuel consumption, an additional requirement is to produce steels that have a high strength to weight ratio.

A new martensitic Fe-Al-C alloy meets all these requirements with flying colors. Moreover, it has the potential for a broad range of industrial applications because its properties can be readily adjusted by applying straightforward heat treatments. The unique combination of ultra high strength and lower density together with the cost effective and lean composition makes this alloy an ideal bearing steel.

However, steels used in industry are exposed to hydrogen containing corrosive environments both during the production cycle and during its lifetime. Therefore, it is of utmost importance to thoroughly understand mechanism of hydrogen embrittlement in this promising Fe-Al-C alloy before it can be used in industry.

The present project will evaluate the hydrogen embrittlement in this new Fe-Al-C alloy by adequate and high resolution techniques.

Study of the hydrogen induced degradation of austenitic steels

Lisa Claeys, in cooperation with VUB

For a long time, face centered cubic (FCC) steel types were considered insensitive to hydrogen embrittlement because of the low hydrogen diffusivity. This idea arose from hydrogen research on body centered cubic (BCC) steels indicating that mobile hydrogen is most harmful as it can readily diffuse to vulnerable locations in the steel microstructure. However, in recent publications, it was shown that FCC steels also suffer from hydrogen embrittlement.

The ongoing PhD has mainly focussed on the interaction between hydrogen and stainless steels including duplex stainless steel and austenitic stainless steel so far.

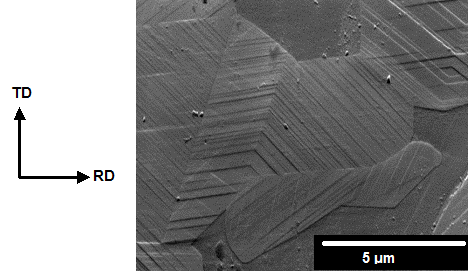

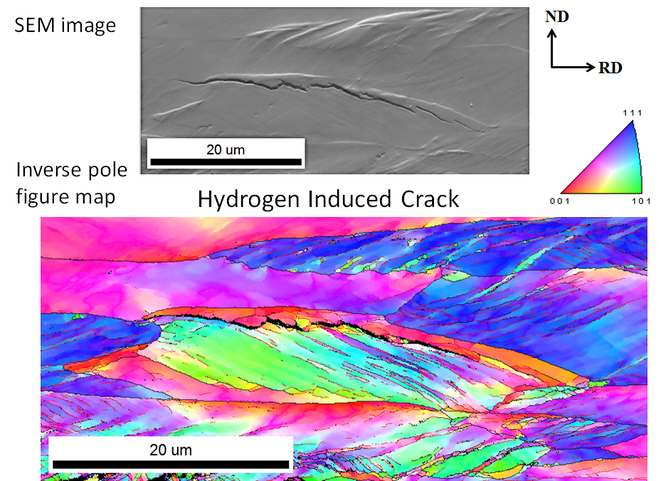

Electrochemical cathodic hydrogen charging of duplex stainless steels resulted in very high hydrogen concentrations, up to 700 wppm. Moreover, during the charging procedure, plastic deformation features were induced in the austenite phase due to the high internal stresses inherent to duplex stainless steels. An image is shown below. Charging lasted for 18 hours.

Slip band formation in the austenite fraction of a duplex stainless steel due to hydrogen charging

The interaction between hydrogen and the microstructure is thus very complicated in the case of austenitic steels. Hydrogen might also alter the operative deformation mechanism during plastic straining. This could lead to twinning or the formation of martensitic phases. The main parameter defining the active deformation mechanism is the stacking fault energy. Hydrogen is stated to decrease the stacking fault energy.

The main future goal of the ongoing PhD is to study hydrogen embrittlement of twinning induced plasticity (TWIP) steels. TWIP steels have a high manganese content (>17 wt%) which causes them to be austenitic (FCC) at room temperature. They combine a high strength with large elongations at fracture and a high energy absorption potential. The properties are a result of the alternative deformation mechanism, i.e. twin formation.

The twins can be considered as extra intragranular obstacles that inhibit dislocation movement leading to the extraordinary combination of properties. Owing to these exceptional properties, TWIP steels have a lot of potential for applications in automotive, oil and gas industry. Literature contains contradictory data on the interaction of hydrogen with the microstructure of TWIP steels.

This PhD aims therefore at elucidating the effect of hydrogen on the microstructure and embrittlement of TWIP steels and at contributing to the knowledge based creation of more hydrogen embrittlement resistant TWIP steels via the appropriate alloying strategy.

Hydrogen permeation in steels

Emilie Van den Eeckhout, in cooperation with VUB and SIM

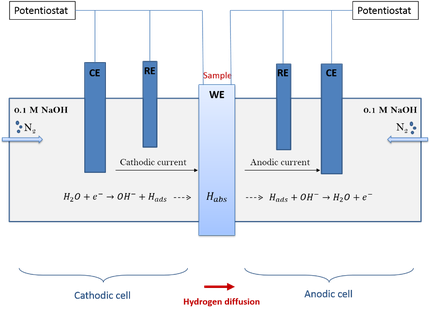

Hydrogen diffusion is one of the main parameters controlling hydrogen embrittlement. Therefore, in this study, the diffusivity of hydrogen was investigated. The technique, based on the permeation cell of Devanathan and Stachurski, allows us to calculate the hydrogen diffusion coefficient.

A schematic representation of the permeation set-up is given below. Materials having different microstructures are evaluated in order to correlate the microstructural features with the hydrogen diffusivity.

In the second part of this research the hydrogen diffusivity in a material subjected to a constant tensile load was examined. Special equipment is added to the permeation cell so that a constant load can be applied during the test. In this case, the influence of stresses on the hydrogen diffusion through the microstructure was investigated.

Hydrogen cracks in steels

Aurélie Laureys

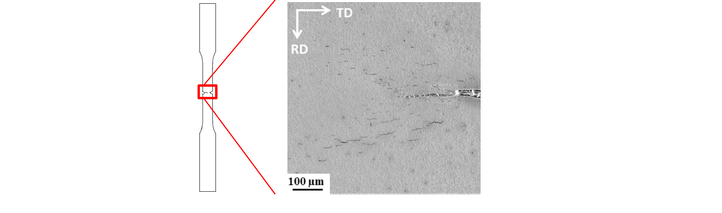

In this work, different aspects of the hydrogen induced cracking phenomenon were studied. First, an extensive assessment of the hydrogen induced cracking behavior of an industrial high strength steel, i.e. TRIP steel (a complex multiphase material), was carried out.

Hydrogen induced crack formation at notch in tensile tested TRIP-steel

Second, a more fundamental investigation of hydrogen induced cracking was performed on pure iron. Advanced characterization techniques allow to assess the crack initiation and propagation mechanisms occurring during hydrogen induced cracking.

Hydrogen induced crack in deformed pure iron studied by EBSD

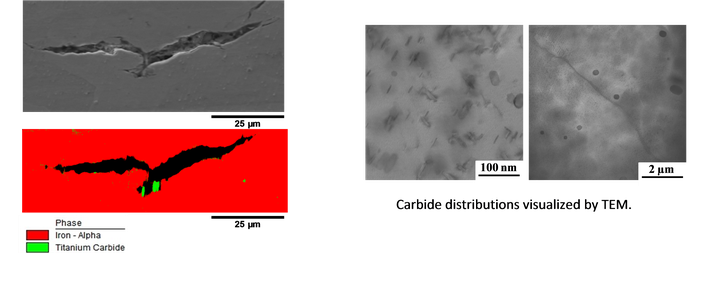

Third, the effect of carbide particle addition to a simple ferritic matrix was investigated. Introducing such particles should reduce the hydrogen embrittlement susceptibility of materials. However, the role of such particles in the hydrogen induced cracking phenomenon has not yet been assessed and was, therefore, investigated in the current study.

Link between carbide and hydrogen induced cracks studied by EBSD

Fourth, the developed methodology and techniques are used to try and simulate real life cracks in nuclear pressure vessels. Hydrogen creates problems in the nuclear power plants of Doel and Tihange, since the presence of hydrogen flakes (hairline cracks) in the reactors jeopardizes the safety of the plants. The role of hydrogen in the possible crack propagation of the current cracks is a key issue here.

Interaction between steel microstructure and hydrogen

Tom Depover

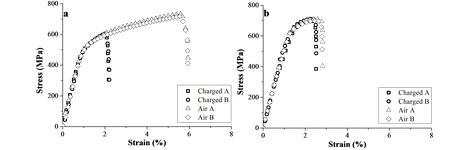

To start, the interaction of hydrogen (H) with advanced high strength steels was considered. The impact of H on the mechanical properties of TRIP and HSLA steel was evaluated by in-situ H tensile tests on notched tensile specimens.

The corresponding results on both H charged and uncharged samples are presented in the figure below. A high hydrogen embrittlement (HE) degree of 60% was measured for TRIP, while only 8% of ductility loss was found for HSLA.

This was correlated to the presence of Nb- and Ti-based precipitates, providing effective trapping sites for H, in this way decreasing the H diffusivity.

Stress-strain curves for TRIP (a) and HSLA (b). Similar tests indicated with A and B

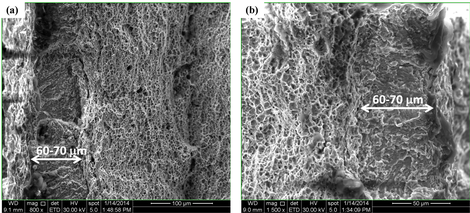

The H induced mechanical degradation of DP steel was studied with tensile tests under variable charging conditions. Comparison between the outcomes of the charged and uncharged tests allowed to visualize the effective H diffusion distance into the sample during the test. The distance H can diffuse at 5 mm/min was about 65 µm.

A fractography study indeed proved that the brittle H induced features were present over a distance equivalent to the distance H can diffuse during the test (cf. the figure below).

Detailed SEM image of both left (a) and right (b) side of the fracture surface of the sample tested at cross-head deformation speed of 5 mm/min without H pre-charging. The brittle zone is shown

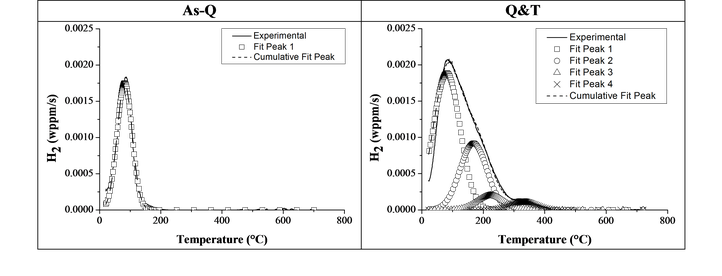

Then, the interaction of H with lab cast alloys was studied. The effect of carbide addition was evaluated in Fe-C-X alloys. Thermal desorption spectroscopy was done on all Fe-C-X materials for both the as-quenched (as-Q) and quenched and tempered (Q&T) condition. The TDS spectra of Fe-C-Ti in both conditions, together with their deconvoluted peaks, are presented in the figure below.

Considering the as-Q condition, only one peak was observed showing activation energies of about 27 – 30 kJ/mol. This first peak was therefore attributed to H trapped by martensitic lath boundaries. When considering the Q&T condition; the additional peaks in the spectra were attributed to the presence of small TiC which were able of trapping a high amount of H, resulting in 3 peaks with activation energies in the range of 50-71 kJ/mol.

TDS curves of Fe-C-Ti (alloy B) in the as-Q and Q&T condition (heating rate: 600°C/h)

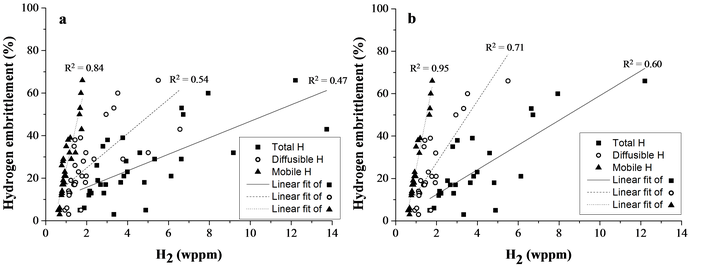

Three different types of H were determined, i.e. total H amount (by melt extraction), diffusible H content (by hot extraction) and mobile H content (the hydrogen lost during a 1 hour vacuum treatment; calculated by subtracting the TDS-curve with 1 hour vacuum from the TDS-curve without 1 hour vacuum, i.e. direct charging).

This mobile H is correlated to H trapped at dislocations.

The relation between these different types of H and the degree of HE is plotted (cf. part (a) of the figure below). For this purpose, alloy A, B and C for each Fe-C-X grade in the as-Q and Q&T condition was included (30 materials).

The correlation improved for total over diffusible to mobile H. Moreover, when Fe-C-V alloys were excluded, since they did not show a significant plastic deformation, (cf. part (b) of the figure below), a R² of 95% between the degree of HE and the amount of mobile H was achieved.

This clearly indicated the crucial role of H trapped by dislocations which is linked to the enhancement of the dislocation mobility by the presence of H as proposed by the HELP mechanism.

Degree of HE vs. total, diffusible and mobile H content for Fe-C-X– alloy A, B and C in the as-Q and Q&T condition (a). The Fe-C-V alloys were excluded in (b) to illustrate the correlation between mobile H and HE for alloys which failed past the macroscopic yield strength.