Material and failure analysis

Several Characterization techniques exist to investigate the microstructure of a material or analyse failure post mortem:

-

Light optical microscopy (LOM)

standard visualization technique with 3D visualization option -

Scanning electron microscopy (SEM)

A scanning electron microscope (SEM) is an imaging technique that uses electrons to visualize the sample surface, the use of electrons results in a higher resolution. SEM can reach a resolution of more that 1 nanometer ant the device operates in a high vacuum.

- Electron backscattered diffraction (EBSD):

Electron Backscattered Diffraction (EBSD) is a Scanning Electron Microscopy (SEM) based technique. It allows for microstructure quantification, the measurement of texture, grain and phase boundary characterization, phase identification and strain determination in crystalline multiphase materials of any crystal structure. The use of this technique allows a better understanding of the mechanisms responsible for the fracture of materials.

- Energy dispersive X-ray detection (EDX):

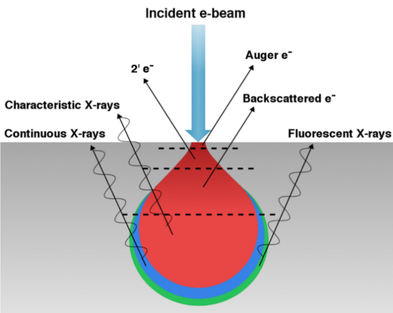

Considering the electron interaction volume in the sample caused by the primary electrons originating from the electron gun of the SEM, different types of interactions are present. Characteristic X-rays can be used in energy dispersive X-ray spectroscopy to detect and characterize the different elements present in the sample. According to Moseley’s law, each element has its own characteristic X-ray wavelength.

-

Transmission electron microscopy (TEM)

In the transition electron microscope or TEM, a beam of electrons is transmitted through an ultrathin sample. While passing through it, the beam interacts with the sample whereby an image is formed. This image is magnified and focused onto an imaging device such as a fluorescent screen, or detected by a sensor such as a CCD camera. Since the TEM uses electrons as source instead of light, a resolution is reached which is thousand times better than with an optical microscope. -

X-ray diffraction (XRD)

X-ray diffraction is used to investigate the atomic arrangement of a crystal. An atom can scatter X-rays in all directions, but when atoms are periodically arranged, i.e. in a crystal, there are certain directions and angles in which the outgoing X-rays have a constructive interference. This occurs when Bragg’s law is satisfied. Since different phase have a different atomic arrangement, it is possible to distinguish several phases with XRD in a heterogeneous compound.

-

Vickers and Brinell hardness

Hardness testing enables the evaluation of material’s properties, such as strength, ductility and wear resistance. A hardness test is typically performed by pressing a specifically dimensioned and loaded object (indenter) into the surface of the material you are testing. The hardness is determined by measuring the size of the impression left by the indenter.

-

Tensile testing

Tensile testing allows to get information about the tensile strength, yield strength and ductility of the metallic material. Different deformation rates can be applied from 0.0001 mm/min up to 500 mm/min with a maximum load capacity of 50 kN.

The tensile machine of Tinius Olsen 50ST -

Spark source optical emission spectroscopy (SS-OES)

This is an quick technique to perform a quantitative metal analysis. It has a high sensitivity and reproducibility and has excellent detection levels for carbon, nitrogen and oxygen.