Structural glass testing

Overview

Structural safety of glass building components, such as glass beams, glass columns, walkable glass floors, and their connections is of utmost importance. To ensure sufficient structural safety and load-bearing capacity – also in partly or fully broken condition - laminated solutions, possibly provided with (stainless) steel reinforcement are typically used, which however typically provide a high dependency on temperature and loading time. Often well-chosen experimental testing is essential to validate sophisticated numerical models.

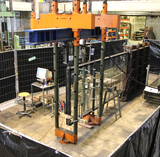

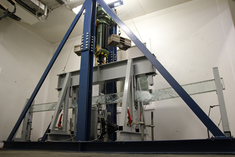

At the Magnel-Vandepitte Laboratory, test setups are often custom-made on project basis. However, several test setups for structural glass component testing are readily available, such as:

- bending and (lateral torsional) buckling setups;

- time/temperature depending mechanical testing of structural glass components at conditioned temperature and relative humidity in a climatised test chamber of 3 m by 4 m (+5° C to +65° C);

- shear wall test setup;

- cold bending test setup;

- scattered light polariscope (SCALP)

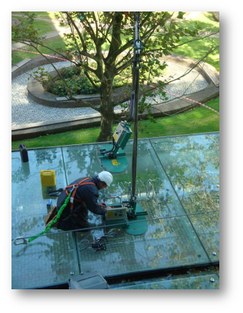

In addition, the Magnel-Vandepitte Laboratory has a long standing tradition in performing on-site expert advice on technical detailing, installation and damage investigation of glass in construction, architecture and facades, but also in marine and automotive sector as well as in very specific industrial installations and applications.

|

|

|

|

|

|

|