Specialized laboratory tests

Overview

The Magnel-Vandepitte Laboratory has specialized equipment and expertise for the performance of laboratory tests on building materials. The laboratory is renowned for its materials research as well as for its research on the structural behaviour, going from micro- or nanoscale till large scale tests.

The infrastructure comprises:

- A unique central testing hall for large-scale load testing (shear resistance tests of hollow core slabs, bending tests on prestressed concrete beams, etc.).

- Testing machines with a capacity of up to 10 000 kN in compression and 2 500 kN in tension.

- A large number of hydraulic jacks for static and dynamic loading tests.

- High precision equipment for accredited calibrations.

- Special equipment for measurements and data acquisition.

- Climate rooms (up to 50°C, 30% - 95% RH – CO2 concentration: 0 - 10 vol%), ovens (up to 1160°C) and freeze chambers (up to -20°C).

- Test configurations for durability tests: Chloride ingress (CTH, diffusion tests) / Chloride profiles (RCT, titrations) / Carbonation (climate chamber) / Alkali-silica reaction (Oberholster test) / Frost-resistance (in combination with de-icing salts) / Acid resistance (TAP – Testing apparatus for accelerated degradation tests) / Submersion in aggressive liquids / Roughness measurements (ALM) / etc.

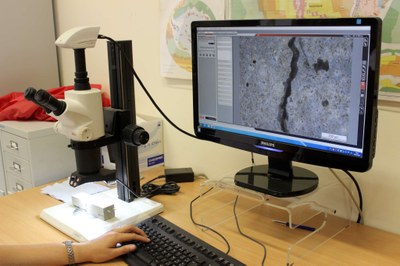

- Optical microscopes and equipment for the preparation of thin sections.

- Equipment for non-destructive testing (e.g. Ultrasonic measurements (FreshCon))

- Weathering of materials by water flow test / algal fouling test / measurement of colour changes

- Numerous equipment for testing the characteristics of various building materials such as cement, aggregates, concrete, masonry, reinforcement, etc.

- Cement: Particle size distribution (Laser diffractometer) / Fineness (Blaine) / Hydration heat (Isothermal Calorimeter Tam Air) / Setting behaviour (Vicat, FreshCon) / etc.

- Aggregates: Particle size distribution (sieve analysis) / Water absorption / Density / Shape factor / etc.

- Fresh Concrete: Consistency (Slump, V-funnel, etc.) / Viscosity (rheometer) / Autogenous shrinkage / Air content / etc.

- Hardened concrete: Hydration heat ((Semi-) adiabatic calorimeter) / Gaspermeability / Waterpermeability / Porosity (Mercury intrusion porosimeter, etc.) / Air content (Air-void analyser) / Colorimetry / Shrinkage – creep / etc.

- Masonry: Shear resistance / Bending resistance / Compression tests / etc.

- Reinforcement: Weld shear force / Tensile tests on prestressed reinforcement / Tests on assembly and transport anchors / Tests on coupling sleeves / etc.

Durability tests: chemical lab - testing apparatus for accelerated degradation tests

Tests on cement: laser diffractometer

Mercury intrusion porosimeter: porosity – air void analyser

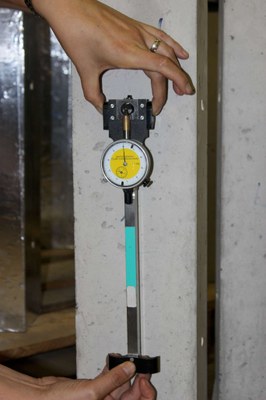

Shrinkage and creep measurements

Mechanical properties: E-modulus – three-point bending test

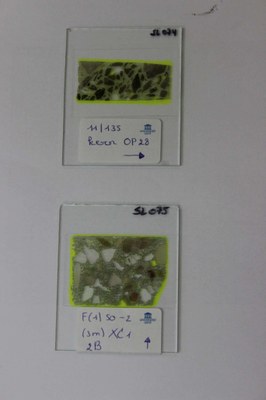

Preparation and analysis of thin sections

Tests on fresh mortar: air content – consistency