Failure of spiral pipe welds under plastic deformation

The strain-based design concept requires pipelines, weld procedures and material properties which allow for large longitudinal straining of the pipe. Traditionally, UOE pipes were frequently used for these project. Due to economical reasons and the availability of coil material with thicknesses above 20 mm, has made the use of spiral welded pipes interesting for their use as an alternative for UOE-pipes. Since spiral-welded pipes are generated with an incomparable production process related to UOE-pipes, the design criteria can not necessarily be used for both types. There is a lack of available literature on systematic studies and the use of spiral welded pipes in a strain based design approach.

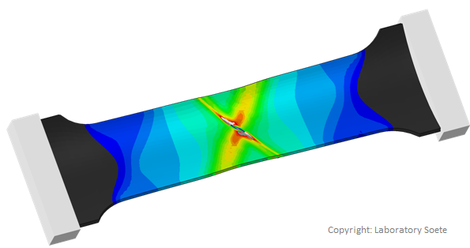

This project aims to investigate the suitability of high strength spiral welded pipelines for strain based design projects considering a coupled numerical-experimental approach. The experimental research focuses on the structural response of medium curved wide plate sections containing the helical weld when loaded in tension. The numerical research consist of finite element analysis of the same curved wide plate tension test. Using this model, various influences of different parameters can be investigated. For example:

- flaw dimension,

- (anisotropic) material response and geometrical properties.