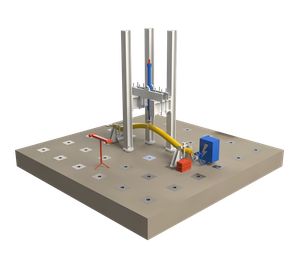

Bend testing

Providing high quality bend testing services for companies that require the perfect curve.

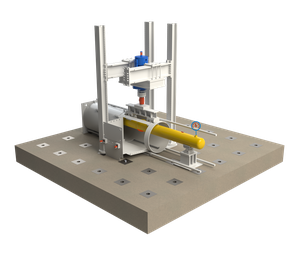

Bend tests are destructive tests, typically performed in a three- or four-points setup using static or dynamic (fatigue) loading conditions. This type of test shows the sample’s response to a combination of tensile (at the convex side), compressive (at the concave side) and shear (along the midline) loading. The compressive stress limit is associated with buckling in some applications (e.g. pipeline). Whereas tensile stresses are defined by fracture (for instance at features such as weld defects, corrosion, pits…). During four-point bending the purpose is typically to detect the weakest location between the inner loading points when experiencing bending stresses.

-

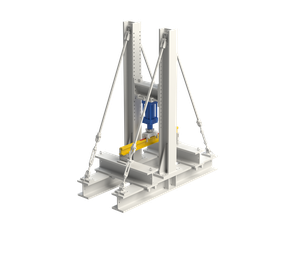

Servo-hydraulic controlled setup

-

custom programmable waveforms: sinusoidal, triangular, square…

-

- Quasi-static load capacity for single load point up to 4000 kN, dynamic load capacity up to 2000 kN

- Test frequency up to 15 Hz

- Dedicated instrumentation to measure applied loads and deformations by using calibrated load cells, LVDT’s, extensometers, clip gauges, strain gauges, highspeed Digital Image Correlation (DIC)…