Component & structural testing

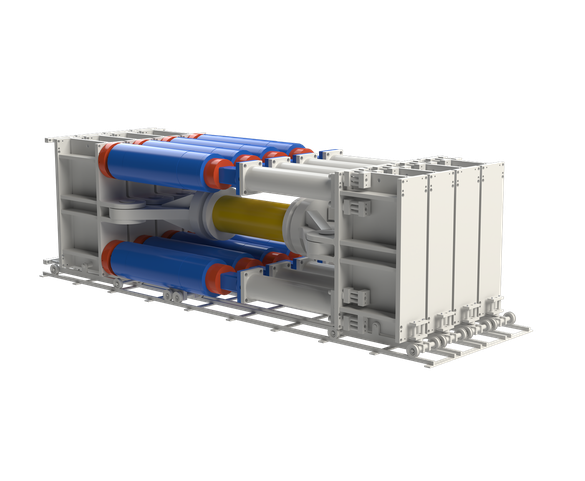

Internal pressure testing

The evaluation of pressure vessels (such as pipeline, heat exchangers, accumulators, …) for their internal pressure capacity in terms of fatigue performance, burst pressure capabilities and leak detection are crucial for their qualification and/or (remaining) lifetime assessment. To this extend, Soete Laboratory designed a set of custom test rigs to perform these assessments with water as a pressure medium.

WHY USE PRESSURE TESTING SERVICES FROM SOETE LABORATORY?

- Obtain accurate test results

- Up to 700bar static & 175bar dynamic

- Ensure the safety, quality and performance of pressure vessels

- Access a range of unique solutions, including bespoke tests

- Full-size performance testing

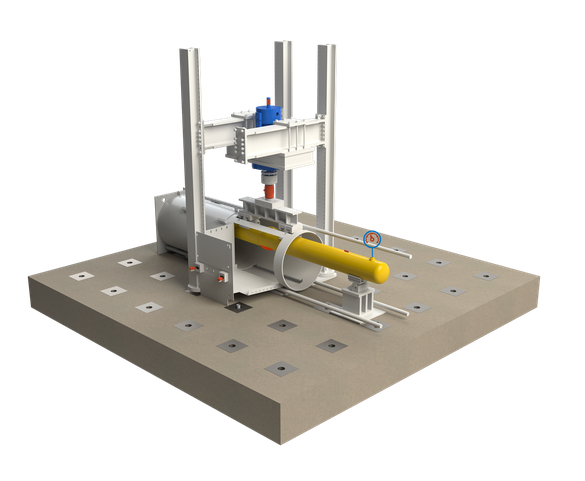

Bend testing

Bend testing services from Soete Laboratory – ensure the quality, performance and robustness of construction materials, components and systems, and comply with applicable regulations.

The bend behavior is typically investigated during a three- or four-point bend test. During bending, the sample is exposed to a complex load state including tension, compression and shear loads. This combination of load allows to determine the ductility, flexural strength, fracture resistance…

WHY CHOOSE BENDING TESTING SERVICES FROM SOETE LABORATORY?

WHY CHOOSE BENDING TESTING SERVICES FROM SOETE LABORATORY?

- Several universal servo hydraulic controlled machines

- Up to 4000kN/loadpoint. imax 40 ton sample size.

- Static and dynamic (fatigue) tests on (full-size) components

- Access a range of unique solutions, including bespoke tests

Custom made test rigs

One of Laboratory Soete’s highlights is the ability to subject large (even full-scale) components and structures to mechanical tests in near operational conditions.

WHY CHOOSE CUSTOM MADE FROM SOETE LABORATORY?

- We transform problems in solutions

- High capacity and full-scale possibilities

- Simulating real-world scenarios

- Provide lab services throughout the project lifecycle

Tension-compression testing

Determining the yield strength, tensile strength, deformation, slip, s-n curve… of the material, component or structure.

WHY USE TENSION AND COMPRESSION TESTING FROM SOETE LABORATORY?

- Several universal machines

- Load capacity up to 8000kN

- Adjustable to perform non-standardized tests

- Static and dynamic (fatigue) tests on (full-size) components

Torque testing

Twisting the sample along its axis determines the shear properties of materials and components. It is a useful test to determine how much of a twist a certain material or component can withstand before cracking of breaking

WHY USE TORQUE TESTING SERVICES FROM SOETE LABORATORY?

- Continious rotation up to 2500Nm (static)

- Custom made higher torque level (e.g. 100kNm)

- Access a range of unique solutions, including bespoke tests

- Provide lab services throughout the project lifecycle