Research

A short introduction

The research group DRAFT (Dedicated Research on Advanced Films and Targets) studies magnetron sputter deposition in general. The group started in the 1980's, with the deposition of Zn/Cu alloys on steel cord wire. From this period stems the tradition to develop its own magnetron sources. Beside the research to industrial interesting materials such as superconductors or (photo)catalytic systems, the group focuses on the fundamental aspects of reactive sputter deposition.

Our long tradition in magnetron sputtering and high-level, fundamental research resulted in an international status on reactive sputtering, with many publications & presentations, the organization of the bi-annual, international symposium "Reactive Sputter Deposition", D. Depla as secretary of the thin film division of the IUVSTA and the presidency of D. Depla of the Belgian Vacuum Society.

Realizing the benefits of close collaboration with the industry and knowing the high demand for test-depositions and small-scale research projects, our research group offers the perfect solution for each interested party: DRAFT, which is your partner for Dedicated Research on Advanced Films and Targets.

Mission statement

At DRAFT we want to become the recognized leader in the understanding of thin film growth by reactive magnetron sputtering and to enjoy research by experiments and simulations.

More about magnetrons ...

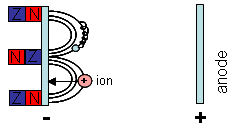

The discharge

Magnetron sputtering is based on the generation of a magnetically enhanced glow discharge in vacuum. When a sufficiently high DC voltage is applied between two electrodes in a confined area at a reduced gas pressure, the gas can be ionized and an electrical discharge can form. The term “glow” refers to the light emission that can be observed in such discharges. The discharge is maintained because positive discharge gas ions are accelerated towards the cathode. The resulting ion bombardment leads to the emission of secondary electrons from the cathode. The emitted electrons will be accelerated into the discharge. Hence, they can ionize gas atoms leading to the generation of new ions, thus sustaining the discharge. In a sputter magnetron, the ionization degree of the generated glow discharge is increased by placing magnets behind the cathode. The placing of the magnets results in an elongation of the electron path towards the anode. Hence, the ionisation probability is increased. The “magnetically enhanced glow discharge” is generally referred to as the “magnetron discharge”. When this type of discharge is used for thin film deposition, the process is referred to as magnetron sputter deposition.Sputtering

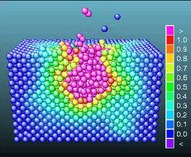

When ions strike the cathode or the target not only electrons are emitted. Indeed, the energetic ion bombardment results in the ejection of target atoms or molecules. This process is called sputtering, a word which finds its origin in the Dutch language, i.e. “sputteren” or “to spit out in small particles and with a characteristic explosive sound”, says the dictionary. The impact of the ion generates a collision cascade. The figure shows a Molecular Dynamics simulation of a collision cascade (taken from the work of H. Urbassek, 1 keV argon bombarding a copper target). The color are related to the energy of the atoms. The simulation shows some atoms leaving the target. In contrast to evaporation the sputtered atoms have an average energy in the order of 10 eV which explains (partially) the different microstructure and the enhanced properties of sputter deposited thin films in comparison with other techniques.Thin film growth

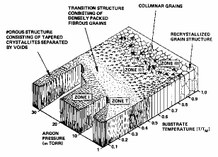

When the sputtered atoms arrive at the substrate, a thin film is formed. The thickness of these films vary between 2 nanometer to 1000 nanometer (or 1 micrometer). The morphology, microstructure and crystallographic orientation of the thin films depend on the growth conditions, which is sometimes depicted in a structure zone model (SZM). For magnetron sputter deposited thin films the first SZM was published by Thornton, and shows the microstructure of sputter deposited metal films as function of the argon pressure and the ratio of the substrate and melting temperature. This latter ratio is also known as the homologous temperature. The research group DRAFT has published an extended version of this model (see papers by Mahieu et al.)Reactive sputtering

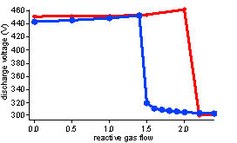

To grow a compound layer when using a metallic target, a reactive gas (e.g. oxygen or nitrogen) is added to the plasma. The reaction between the reactive gas and sputtered atoms on the substrate results in the formation of the compound layer. Compound formation can also occur on the target which changes the overall deposition process and results in complex behavior of the deposition parameters as a function of the reactive gas flow. A typical experiment is performed as follows. The reactive gas flow is increased in steps, and the process parameters are measured when the process has stabilized. Then the same measurement is performed while the reactive gas flow is decreased again in steps. A plot of the process parameters, such as the discharge voltage, shows typically a hysteresis. The research group DRAFT have developed a simulation code to describe this (and many other) kind of experiments.Some history

Sputtering was discovered by W. Grove in 1852 while investigating discharge tubes using a silver needle cathode. He observed film deposition on the anode plate. Because of his poor vacuum conditions, he probably deposited silver oxide. By reversing the voltage, he sputtered the deposit off again.