Wear testing services

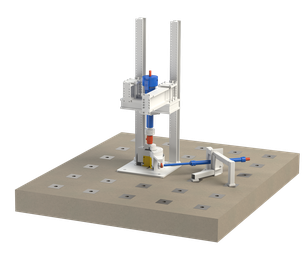

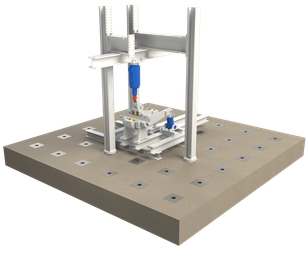

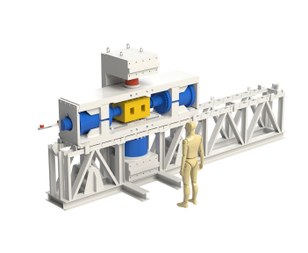

A broad range of wear test rigs offers the possibility to investigate tribological problems in different scales.

At Labo Soete from a more simple, standardized small-scale coupon-level test rigs (e.g. pin-on-disc, block-on-ring, erosion, scratch testing) to the more complex, closer to application large-scale level testers are available. Each setup offers unique settings that enables to cover a broad range of test matrix and control on the testing environment. The testing method is carefully selected according to best possible match the operating conditions of the investigated material part.

- Agricultural sector: different ploughshare materials compared and ranked based on pin-on-disc tests.

- Harvester machine parts investigated in different erosive environment on a centrifugal erosion tester.

- Manufacturing machines: newly developed materials are tested against scratch abrasion.

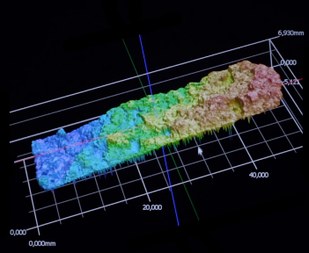

- Oil and pipe industry: pipe and pump material lifetime investigated in slurry-erosive environment in a slurry pot system.

- Mining industry: Effect of erosion-corrosion investigated in machine components involved in dredging.

- Wind turbines: different gears and lubrications are investigated in a gear-gear contact FZG.

- Medical sector: newly applicable bioinert polymer composites are investigated in a pin-on-disc setup.