Colorimetric nanofibers for sensor applications

Small fibers, big warnings: how tiny threads visualize threats.

Sensors are everywhere. They are important to us, because we count on them to give us information about the weather, our health, our food, even our safety. By investigating colorimetric nanofibers, we are trying to design next-level sensors that are light, fast, smart and visual. We are trying to understand the interactions between polymers and stimuli-sensitive dyes inside the nanofibers, to produce and optimize their color change in response to an external trigger. This way, they can warn us against factors that might threaten our health or our safety.

Have you noticed how your phone “senses” the proximity of your ear so it turns off your screen when you are calling? Has it surprised you at all how fast your health can be evaluated by a simple urine strip? Have you ever questioned how the police know you've had too much to drink by just blowing into a little box? You don’t have to look very hard indeed; a world without sensors is unthinkable. From smoke to food freshness detectors, we strongly rely on them to warn us whenever something is wrong. And although the basic understanding of a sensor remains the same – it senses something – today’s society wants them to be smarter, lighter and faster than ever. On top of that, sensor signals should be easy to understand, because we would all like to use them in our daily lives. With our research on colorimetric nanofibers we are trying to fulfill these requirements.

The explanation is in the name: nanofibers are fibers with a diameter at the nano-scale, a thousand times thinner than a human hair. Very tiny threads indeed, only visible under an electron microscope. They can be produced by a unique process called electrospinning, in which they are drawn from a viscous polymer solution under influence of an electrical field. If all the process parameters are at the right conditions, the result is typically a stand-alone membrane composed of randomly oriented nanofibers, looking similar to a piece of paper. Alternatively, they can be spun onto a support, acting more like a coating. Depending on the polymer used, the mechanical and thermal properties of the nanofiber mat can vary widely but they all have some properties in common, and these happen to be ideal for sensor applications: they are versatile, meaning they can be used in many different circumstances, they are light, so they are easy to handle, and most importantly, they are very porous, which provides a high contact area with whatever they need to sense.

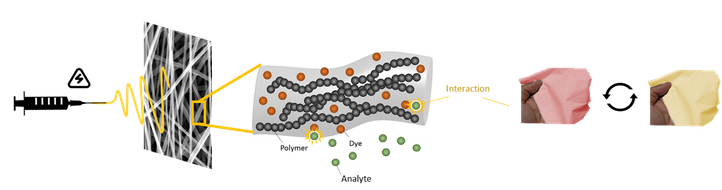

So how do we turn these nanofibers into sensors? By adding color! Stimuli-sensitive dyes are defined as small molecules that are capable of absorbing different parts of the visible light spectrum depending on the state of their environment. Like a chameleon, the dye senses its environment and changes its color accordingly. Examples are halochromic dyes which have different colors at different pH values, mechanochromic dyes that respond to deformation, thermochromic dyes that change with temperature or photochromic dyes that are stimulated by light. If such a stimuli-sensitive dye is incorporated into a viscous polymer solution and subsequently electrospun, colorimetric nanofibers are created. They are designed to change color in response to a specific external stimulus.

Designed indeed, because there are a few steps to consider in the process. The stimuli-sensitive dyes can be incorporated physically or covalently into the nanofibrous matrix. Physical incorporation is the most straightforward method as it just involves mixing the dye and the polymer with one another. But here’s the catch: as simple as it is to get the dye into the matrix, it’s equally simple to get it out. This phenomenon, where the dye tends to migrate out of the nanofibrous matrix, is called leaching. Leaching can be prevented by covalently linking the dye to the polymer. In this case, understanding the chromophore of the dye – the molecular unit responsible for the color change – is crucial as this allows us to manipulate the final colorimetric response of the nanofibers. In-depth analysis of the optical behavior of different dye-polymer systems helps us to understand which, often unexpected, interactions between dye and polymer occur which, in turn, allows us to tune them. Of course, depending on the foreseen application, the dye best suited for the job should be combined with the most appropriate polymer carrier, having specific properties of its own. At the end of the optimization process, a sensor meeting the end-user’s wishes is created, consisting of very small fibers, yet capable of warning you against small or even large threats in a visual, easy-to-understand way.

Research towards colorimetric nanofibers is strongly interdisciplinary and based on a collaboration between the Department of Materials, Textiles and Chemical Engineering and the Department of Organic and Macromolecular Chemistry at Ghent University. This way, expertise in materials science, chemical engineering and supramolecular chemistry is combined to design, produce, analyze and manipulate several dye-polymer systems. We have been focusing on poly(N-isopropyl acrylamide) and poly(2-oxazoline) polymer systems as well as inorganic silica networks, combined with several responsive dyes such as the halochromic methyl red and rose Bengal. Production and electrospinning of the dye-polymer systems are performed and optimized in-house. A thorough understanding of the produced materials is achieved by several analysis techniques. While optical and electron microscopy reveal what the microstructure of the material looks like, infrared spectroscopy tells us something about the interactions between the different components – dye and polymer – in that structure. Insight into these interactions can be underpinned by theoretical models simulating the dye-polymer system. The study of color can be performed by UV-Vis and fluorescence spectroscopy.

Our work has already resulted in original breakthrough insights into the actual dye-polymer microstructure and interactions, and their influence on the electrospinning process, material morphology and final sensor properties. Personal care, safety, biomedicine, food quality and environmental monitoring are only a few of the many application areas where advanced colorimetric sensors can be useful.

Further information

Parts of this research were published in cover articles and received several awards:

- Ella Schoolaert - 1st prize for poster at 6th International Conference on Electrospinning (China, 2019)

- Ella Schoolaert - 1st prize for oral presentation at 2nd International Caparica Conference on Chromogenic and Emissive Materials (Portugal, 2016)

- Ella Schoolaert - 1st prize for poster at 4th International Conference on Electrospinning (Italy, 2016)

- Thierry De Meyer - Jozef Plateau Award (Belgium, 2012)

- Lien Van der Schueren – Public award and 3rd prize for master thesis at KVIV Ingenieursprijzen (Belgium, 2009)

Acknowledgements

This research has been and still is part of several Ph.D. projects:

- Dr. ir. Ella Schoolaert (FWO strategic basic research grant 1S05517N)

- Dr. ir. Jozefien Geltmeyer

-

Dr. ir. Thierry De Meyer

-

Dr. ir. Iline Steyaert

-

Dr. ir. Lien Van der Schueren

Contact

Prof. dr. ir. Karen De Clerck (Karen.DeClerck@UGent.be)