The recycling of waste acrylic textiles (European H2020 project REACT)

The REACT project is concerned with the end-of-life of acrylic textiles originating from awnings, umbrellas and outdoor furnishings. These textiles are coloured with pigments and treated with chemical finishes to make them fit for outdoor use, but these substances interfere with the mechanical recycling process, so we have to remove them.

Did you know that in 2015, the global textiles and clothing industry was responsible for the consumption of 79 billion cubic meters of water, 1715 million tons of CO2 emissions and 92 million tons of waste? At the moment, waste recycling processes are still tackled inappropriately in the E.U., while landfill and incineration rates remain high. One of the main problems is that recycled materials are often of inferior quality to virgin materials because of contamination, treatments and inherent degradation. The REACT project thus aims to address this issue for acrylic textiles originating from the outdoor awnings, umbrellas and furnishings sector. While these textiles are but a small part of the global chain, studies show that acrylic fibers are definitely worth recycling, even more so than cotton!

The objectives of the REACT project are:

- Remove 90-95% of those hazardous substances whose presence could adversely affect the quality of the recycled material or prevent their recycling.

- Treat up to 99% of all sewage impurities obtained from the removal steps (e.g. in waste water).

- Obtain a final textile product with yarn coming from 100% recycled acrylic fibers.

- Use the recycled acrylic fibers as a raw material for other production cycles in combination with virgin fibers, to prevent 30% of waste from the outdoor sector (3600 tons).

- Produce recommendations for production chain implementation (management and recovery of production scraps) and design and manufacturing of materials to enhance recyclability, recommendations for technology transfer (to other products and applications), and recommendations for standards.

The first step in the REACT project is the collection, sorting and classification of any acrylic textile waste. In a crucial next step, we analyze this fabric and treat it to remove finishing substances and colorants that affect the recycled material’s quality. Once the harmful substances have been removed and safely disposed of, we will implement a mechanical recycling process to obtain new yarns and eventually fabrics. To maximize the impact of the project, we will transfer any new designs, technology, standards, process implementation, etc. to other industrial sectors.

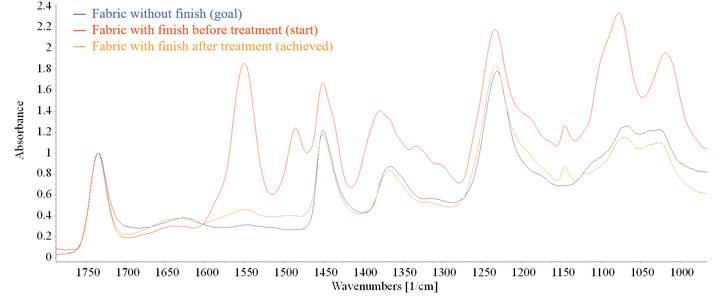

At Ghent University, we analyze the waste fabrics and the chemicals applied unto them, and remove these chemicals. To do the characterization, we use different techniques. Modulated differential scanning calorimetry and thermogravimetric analysis provide information on glass transition temperatures and degradation temperatures, respectively. Fourier transformed infrared and Raman spectroscopy clearly identify the chemical structures that need to be removed, while UV-Vis spectroscopy provides supporting information and quantifies color.

We remove harmful substances from the waste acrylic textiles by means of chemical treatments. For example, multiple resin hydrolysis reactions are carried out under varying environmental conditions. The aforementioned spectroscopic techniques are then used to evaluate the effectiveness of the proposed finish and colorant removal treatments. Tensile tests at the fiber level also give insight into the mechanical properties of the original fibers, and any damage that may be done to the fibers during chemical treatment (which is minimized during process optimization). Finally, scanning electron microscopy visually clarifies what happens to the fiber morphologies.

Further information

Acknowledgements

Funded by the European Commission’s Horizon 2020 programme, the REACT project involves 7 partners in 5 European countries: Centrocot (Italy), Ghent University (Belgium), Parà (Italy), Soft Chemicals (Italy), Jak Spinning (Hungary), CETI (France) and Martel (Switzerland). The project is coordinated by Roberto Vannucci (Centrocot) and is expected to take 3 years. Ghent University started its involvement in September 2019.

Call: H2020-SC5-2018-2019-2020

Topic: CE-SC5-01-2018

Contact

Prof. dr. ir. Karen De Clerck (Karen.DeClerck@UGent.be)