Validation of a Platform for the Electrostatic Characterization of Textile

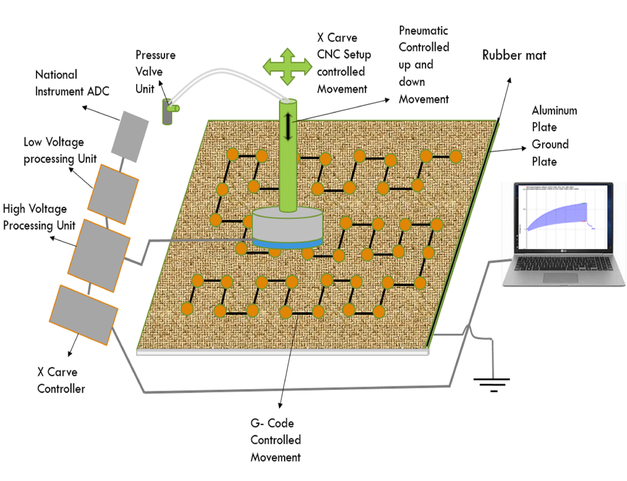

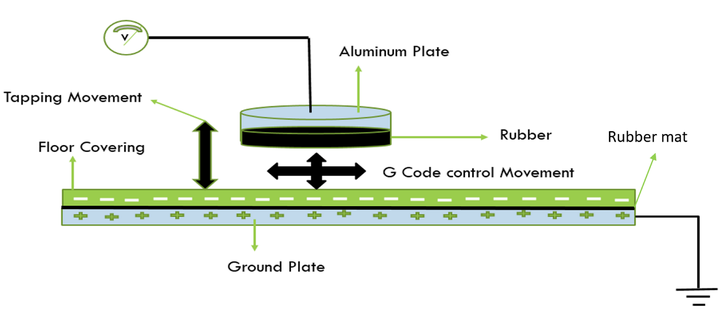

This research aims to validate an electrostatic characterization device that offers a variety of settings for controlling sample electrostatic activation and has a sample size range of up to one square meter. Furthermore, it can move in both horizontal and vertical directions in a controlled manner, providing a variety of possibilities for testing the effect of various movement features on electrostatic charge generation.

After just a few steps on a dry, insulated floorcovering, static electricity may provide an unpleasant but generally harmless shock when a person contacts a door handle. Static electricity was the first type of electric process known to man. As a result, several great but specialist treatises on the subject have been published. However, there continue to be a lot of misunderstandings and misconceptions about static electricity in textile items. Static energy produced by friction can be charged onto textiles and other materials. This may be quite an issue, particularly with floor coverings, as people walking on them can build up a high-voltage electrical charge. The release of accumulated static charge can make people feel uncomfortable, affect or damage electronic equipment, or even present a fire risk, as might be the case at a gas station. As described in the ISO 6356 standard, the walking test is one of the tests used to assess the electrostatic properties. The voltage produced by a person walking on floorcovering is measured in this test. There are two possible reasons for measuring electrostatic charge production in textiles. The first is figuring out how to generate it so that better textiles and floor coverings can be made with less static build-up, and the second is optimizing it so that it can generate Nano energy and be used to recharge low-power sensors and electronic gadgets.

Electrostatic charges are generated when two surfaces come into touch and are then separated. The transferred charges cannot travel if one of the bodies is an insulator, which causes charge accumulation. The positive excess of charges will be accumulated in one of the two bodies, while the negative excess will be generated in the other. The polarity and the amount of charge transfer and build-up are mostly determined by the chemical and physical makeup of the materials. Electrical surface resistance and volumetric resistance of the materials are additional aspects that are crucial for charge accumulation and transfer between surfaces. The primary factors that govern the formation of electrostatic charges are surface texture, contact pressure, separation distance, and speed of friction or separation. Temperature, relative humidity, and the kind and volume of the air surrounding the surfaces are examples of external elements that might influence the formation of electrostatic charges on the surface. The amount of built-up charge on the body is determined by a number of elements in addition to these basic ones. Shoes, flooring, surface coatings, walking pace, step height, and step pressure are a few of them.

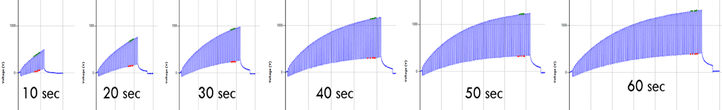

In validating the electrostatic characterization device, the walking mode produces the same outcomes as the standard device's human walking mode. Additionally, this device could characterize the electrostatic behaviour of floorcoverings while walking on them. The walking parameters were optimized. The automatic electrostatic characterization apparatus could control six parameters (frequency, pressure, testing time, stepping height, dwell time, and various sample sizes). Peak and peak-to-peak electrostatic voltage were used to study the impact of various parameters on the formation of electrostatic charge. Peak voltage rises with frequency, stepping height, test duration (until saturation point), applied pressure (at the same frequency), and sample size but falls with longer dwell times at the same frequency. At a given frequency, the peak-to-peak voltage rises with increasing frequency, stepping height, test duration till saturation, and applied pressure but falls with increasing dwell time. The peak and peak-to-peak voltages were used to validate the many motion-related factors regulated by this device to determine how they affected the overall output voltage. Due to rapid movement at higher frequencies, more electrostatic charges are produced. Since a lower dwell time results in a greater frequency, a lower dwell time increases electrostatic charge. While performing automated static testing, the dwell time will significantly impact the outcome and should be clearly established. Due to greater exposure to air during movement, electrostatic charges increase as the stepping height increases. Over a threshold pressure, the influence of pressure will no longer be as significant because the shift in static charges is no longer as great over one bar. Testing should always be done on a sufficiently big testing sample to be representative. The increase in electrostatic charges with higher sample sizes is due to greater material exposure over a wider surface area, with the influence being most substantial when going to very small samples. The same is true for the testing duration; it should be long enough to allow for saturation, which was reached after 60 seconds in this study's testing. This research provides specific instructions on how to use settings and what metrics to track when utilizing automated static testing devices. The devices must be used for a minimum of one minute during testing, step on samples at least one-meter square, employ pressure of more than one bar, and explicitly indicate dwell time and stepping height because these factors affect the formation of static charges.

The walking simulator walks at 120 steps per minute which is the standard speed to walk in electrostatic testing of floorcoverings according to ISO 6356. The results show that the walking simulator produces less electrostatic charges during walking on the floorcoverings than a human walking on them. However, the walking simulator could characterize the floorcovering electrostatic behaviour with higher repeatability with all the predefined factors. The AFM (Automated Foot Machine) is a better tool for research purposes with much lower variability in testing results due to fixed applied pressure, stepping height, dwell time, frequency, resistance, and capacitance. According to the four fundamental modes of electrostatic devices, the automated foot working principle is based on a single-electrode mode with a variable sample size that can fully characterize the electrostatic behaviour of floorcoverings and other textiles in a more repeatable and reproducible way.

Further information

- Tahir, H. R., Malengier, B., Van Daele, D., & Van Langenhove, L. (2021). Validation of a Platform for the Electrostatic Characterization of Textile. Electronics, 11(1), 115.

- Tahir, H. R., Malengier, B., Van Daele, D., & Van Langenhove, L. (2022). Validation of a Textile Material’s Electrostatic Characterization Device for Different Parameters and Their Effect on the Electrostatic Charge Generation. Materials, 15(16), 5716.

- Tahir, H., Malengier, B., Van Daele, D., Tseghai, G. B., & Van Langenhove, L. Walking Simulator for the Electrostatic Characterization of Floorcoverings and Body Voltage. Available at SSRN 4137326.

Acknowledgements

The authors would like to thank the Department of Materials, Textiles and Chemical Engineering, Ghent University (Belgium) as well as the PhD research funding (scholarship scheme HRDI-UESTPs/UETs Phase-1) by the Higher Education Commission (HEC), Pakistan for providing research facilities.

Contact

Prof. dr. ir. Lieva Van Langenhove (Lieva.VanLangenhove@UGent.be)