Silica nanofibrous membranes for advanced engineering applications

Stand-alone inorganic membranes via the combination of electrospinning and sol-gel technology

Over the past decades, global awareness with respect to environmental problems has significantly increased. To grapple these problems, research and development in advanced materials for the process intensification of various technologies needs to be undertaken. Therefore, there is a high demand for materials that can withstand harsh environments. Development of such highly inert materials, namely silica-based nanofibrous membranes, is under investigation within this work.

Initially, electrospinning of nanofibers was explored with only one of the material classes, namely polymers. This allowed for a relatively straightforward development of high-tech nanofibrous products (e.g. gas filters and protective clothing). Gradually, research towards the electrospinning of the other material classes increased, since the chemical and thermal stability of organic polymers is mostly limited, and the production of more stable polymeric membranes requires typically harmful solvents. One of the most promising research lines in this field is the development of ceramic nanofibers. They are expected to have a much better chemical and thermal resistance, and keep the benefits of polymeric nanofibrous membranes in terms of porosity and high surface to volume ratio. In addition, the introduction of nanostructured ceramics instead of bulk ceramics allows for transformation of their conventional properties.

In general, the state-of-the-art literature makes use of a two-step production process for ceramic nanofibers. First the electrospinning solution, consisting of an inorganic precursor material (mostly metal alkoxides) and a well-spinnable organic polymer, is drawn into nanofibers under the appropriate conditions. In the second step, a calcination treatment at elevated temperatures is performed to remove the organic polymer, and to allow sintering and chemical conversion of the inorganic precursor material. This calcination results in a nanofibrous structure with a lot of macro- and/or microscopic damage, which results in more fragile membranes with a significant increase of the brittleness compared to the untreated structure.

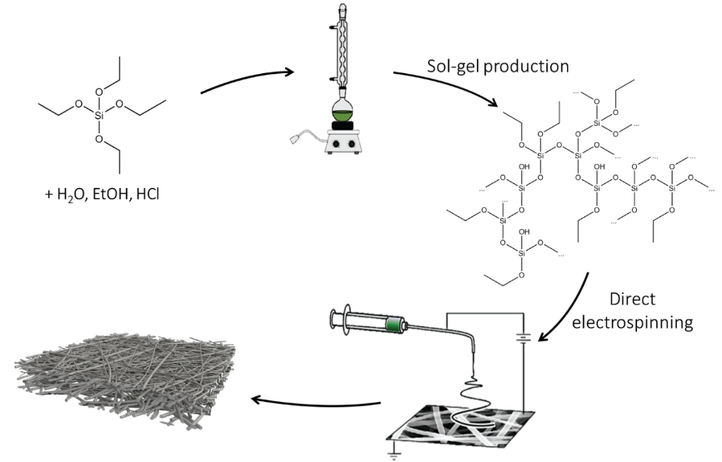

To improve the mechanical properties and fiber morphology, production of ceramic nanofibrous membranes without the incorporation of an organic polymer is preferred. Direct electrospinning of a sol-gel system is reported as a possible technique. Therefore, the CTSE and SCRiPTS research groups investigated the use of a silica sol-gel system to produce flexible, stand-alone nanofibrous membranes. Direct electrospinning of a sol–gel solution of a tetraethyl orthosilicate (TEOS) precursor eliminates the need for a post-production removal of the organic polymer component. This results in dense silica nanofibers with superior mechanical properties, without a rough and uneven surface of the fibers, as schematically depicted in the figure below. In addition and even more important, it offers the benefits of a simple, more tunable material design, opening up the application potential towards advanced engineering applications such as separation/purification and catalysis.

Further information

Publications:

- Loccufier, E., Geltmeyer, J., Daelemans, L., D’hooge, D., De Buysser, K., & De Clerck, K. (2018). Silica nanofibrous membranes for the separation of heterogeneous azeotropes. ADVANCED FUNCTIONAL MATERIALS, 28(44). https://doi.org/10.1002/adfm.201804138

- Geltmeyer, J., De Roo, J., Van den Broeck, F., Martins, J., De Buysser, K., & De Clerck, K. (2016). The influence of tetraethoxysilane sol preparation on the electrospinning of silica nanofibers. JOURNAL OF SOL-GEL SCIENCE AND TECHNOLOGY, 77(2), 453–462. https://doi.org/10.1007/s10971-015-3875-1

- Geltmeyer, J., Van der Schueren, L., Goethals, F., De Buysser, K., & De Clerck, K. (2013). Optimum sol viscosity for stable electrospinning of silica nanofibres. JOURNAL OF SOL-GEL SCIENCE AND TECHNOLOGY, 67(1), 188–195. https://doi.org/10.1007/s10971-013-3066-x

- Geltmeyer, J., Vancoillie, G., Steyaert, I., Breyne, B., Cousins, G., Lava, K., … De Clerck, K. (2016). Dye modification of nanofibrous silicon oxide membranes for colorimetric HCl and NH3 sensing. ADVANCED FUNCTIONAL MATERIALS, 26(33), 5987–5996. https://doi.org/10.1002/adfm.201602351

- Geltmeyer, J., Teixido, H., Meire, M., Van Acker, T., Deventer, K., Vanhaecke, F., … De Clerck, K. (2017). TiO2 functionalized nanofibrous membranes for removal of organic (micro)pollutants from water. SEPARATION AND PURIFICATION TECHNOLOGY, 179, 533–541. https://doi.org/10.1016/j.seppur.2017.02.037

- Loccufier, E., Deventer, K., Manhaeghe, D., Van Hulle, S., D’hooge, D., De Buysser, K., & De Clerck, K. (2020). Degradation kinetics of isoproturon and its subsequent products in contact with TiO2 functionalized silica nanofibers. CHEMICAL ENGINEERING JOURNAL, 387. https://doi.org/10.1016/j.cej.2020.124143

Video:

Acknowledgements

- IWT Strategic Basic Research grant 121241

- FWO SB PhD Grant 1S82920N

- FWO SB PhD grant 1S84322N

- BOF project grant BOF19/24J/102

Contact

Prof. Dr. Ir. Karen De Clerck (Karen.DeClerck@UGent.be)