Electrospun nanofibrous yarns for tissue engineering applications

Solvent electrospinning has been known for several decades now, yet the typical products that are being produced are nonwovens, thereby ignoring an entire range of potential textile products: yarns and wovens. This gap can now be filled as recently the yarn electrospinning process was discovered, allowing to electrospin nanofibers in the form of yarns, opening doors towards a whole new world of end-product possibilities, such as nerve regeneration conduits and tendon tissue engineering

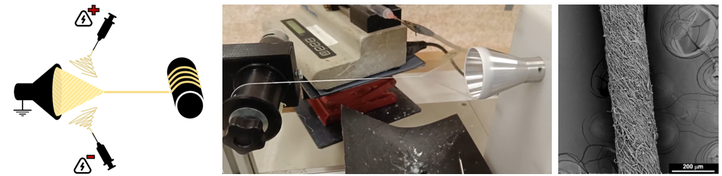

Nanofibers have already proven to have a lot of potential as sensors, wound dressings, water treatment membranes etc. The typical products used for these applications are nonwovens. However, the recently developed yarn electrospinning technique allows the production of nanofibrous yarns. Although all that is needed in addition to the traditional electrospinning setup is a rotating cone collector and a yarn take-up unit, this new technique significantly expands the number of potential end-products for nanofibers.

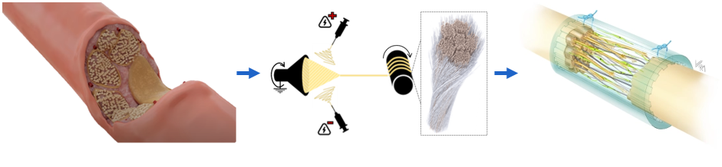

An important potential use of these innovative nanoyarns is tissue engineering scaffolds. Indeed, nanofibers have already proven to have a lot of potential as substrates for nerve regeneration and tendon tissue engineering. Nanoyarns, however, could be the next step in the development of advanced substrate designs. As example, an innovative design for a nerve guidance conduit can be produced with the yarn electrospinning technique. These conduits, which are placed between the ends of a damaged nerve, have the purpose to guide regenerating neurons in order to reconnect the nerve ends and thereby restore the nerve’s motor and sensory functions. For this novel nerve guidance conduit design, several biocompatible poly(ε-caprolactone) nanoyarns are bundled by electrospinning a poly(ε-caprolactone) nanofibrous shell around the bundle.

Research on this topic at CTSE is focused on the understanding of the yarn electrospinning process and the optimization of the novel nerve guidance conduit design by tuning the morphology of the different components of the conduit and by adding biological active cues. On top of that, a lot of attention is given to the mechanical properties of the conduit and its individual components, as the mechanical integrity of the conduit is very important.

Acknowledgements

This research is part of the PhD project of ir. Lucas Schynkel.

Contact

Prof. dr. ir. Karen De Clerck (Karen.DeClerck@UGent.be)