High magnification scanning electron microscopy (SEM) during mechanical testing

Observing deformation mechanism at microscale

The link between a material’s microstructure and it’s performance on macroscale is a crucial aspect to optimize and design novel high performance materials. Thanks to in-situ scanning electron microscopy (SEM) much deeper insights are obtained as we can visualize the deformation and failure of materials at the microscale. This is a promising technique for textile materials, where the fibers are micrometer sized and high magnification is required.

This novel testing set-up consists of a Phenom XL tabletop SEM instrument combined with a microscale mechanical tester from Deben. The mechanical tester is easily put within the SEM chamber allowing to do all kinds of mechanical tests, while visualizing the specimen with SEM. The SEM gives a magnification ranging from 100x to 10 000x, allowing to focus on the microstructural characteristics of the specimens. For example, individual fibres within a textile are easily visualized and can be tracked during the mechanical testing of the fabric material. In addition to SEM images, the load, displacement and strain of the specimen is measured. Furthermore, Digital Image Correlation is also possible, enabling full-field strain measurements in the specimen.

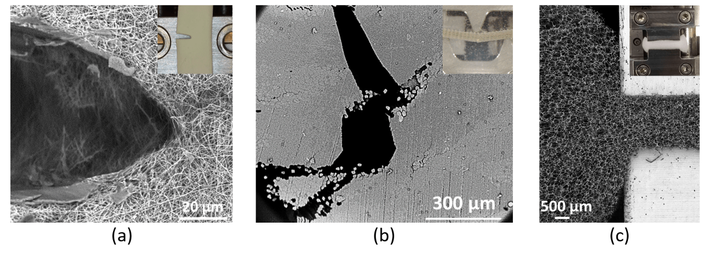

Thanks to this set-up, new insights into the performance of materials can be obtained. For example, we have used it to analyse the deformation behaviour of high-performance filter materials under tension, fibre reinforced composite components crack initiation, and rigid foams that are being compressed, see the image below.

Further information

- Daelemans, L., Verschatse, O., Heirman, L., Van Paepegem, W., & De Clerck, K. (2021). Toughening mechanisms responsible for excellent crack resistance in thermoplastic nanofiber reinforced epoxies through in-situ optical and scanning electron microscopy. COMPOSITES SCIENCE AND TECHNOLOGY, 201. https://doi.org/10.1016/j.compscitech.2020.108504

- Verschatse, O., Daelemans, L., Van Paepegem, W., & De Clerck, K. (2020). In-situ observations of microscale ductility in a quasi-brittle bulk scale epoxy. POLYMERS, 12(11). https://doi.org/10.3390/polym12112581

- Microscale analysis of fibers, matrix and composite materials

Contact

Prof. dr. ir. Lode Daelemans (Lode.Daelemans@ugent.be)