Microscale analysis of fibers, matrix and composite materials

Understanding the deformation and failure behaviour at the microscale level

Micromechanical observations of both composites and their individual components show that there are important differences in behavior at the microscale compared to the bulk scale. Microscale samples show higher ultimate stress and strain values, as well as a different deformation behavior. These are important aspects in order to understand how composites will behave under loading and in failure. These insights are crucial, for example in the field of multiscale modelling.

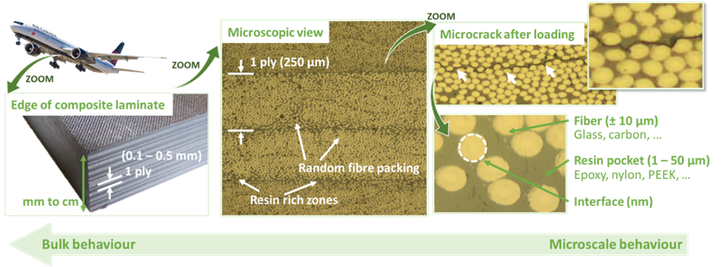

The demand for fiber-reinforced polymer (FRP) composites is surging in many industries as a substitute engineering material for metals due to their fantastic mechanical performance and low structural weight. However, all benefits aside, the production and design of composite parts remains a time-consuming process, especially requiring a lot of experimental iteration. One of the main obstacles in composite design is that the bulk behavior (especially in nonlinear and damage behavior) is not well understood due to the complex microstructure of composites. Composites typically consist out of a stack of plies, wherein each ply contains millions of fibers (diameter 5-20 µm) embedded in a polymer matrix. The fiber and polymer properties, as well as their interaction at the micro-scale, dictate how the end part behaves at the bulk scale. This is also the case when composite start to fail, fracture starts at the individual ply scale and builds up towards total fracture.

We try to overcome this lack of knowledge via measuring and analyzing the microscale deformation behavior of composites and their constituents. In a first phase, focus is put on microscale matrix samples and fiber-matrix interaction. In a second phase, we analyze unidirectional composites which can be combined with finite element modeling. We combine the testing of microscale samples with in-situ observations. In this aspect, our state of the art table-top SEM with in situ tensile stage is crucial. This combined with in situ polarized light microscopy, enables us to study microscale composite behavior at a new level.

The results of this research project will be two-fold, firstly, a better understanding of the (micro)mechanics of composites will be achieved. Secondly, with the obtained knowledge it will be possible to have a more accurate finite element modelling of composite behavior. To obtain the best possible results, this research is based on a close collaboration between the Centre for Textile Science and Engineering and the Mechanics of Materials and Structures research group which are both connected to the Department of Materials, Textiles and Chemical Engineering at Ghent University.

Further information

- Verschatse, O., Daelemans, L., Van Paepegem, W., & De Clerck, K. (2020). In-situ observations of microscale ductility in a quasi-brittle bulk scale epoxy. POLYMERS, 12(11). https://doi.org/10.3390/polym12112581

- More publications

Contact

Prof. dr. ir. Karen De Clerck (Karen.DeClerck@UGent.be)

Prof. dr. ir. Lode Daelemans (Lode.Daelemans@UGent.be)